Market Trends

Key Emerging Trends in the Hollow Concrete Block Market

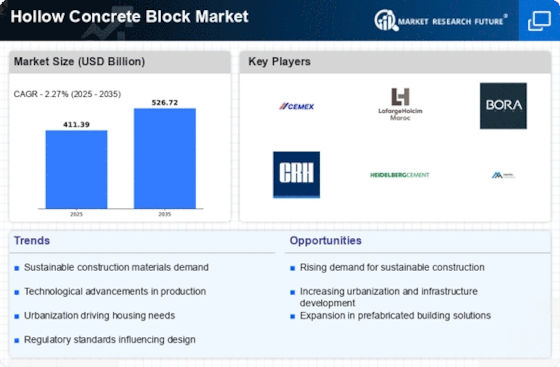

The market trends of hollow concrete block industry are going through dramatic changes, stimulated by a multifactorial convergence that is redefining the construction patterns. A significant shift occurs in terms of using eco-friendly and sustainable building materials. Along with the growth of environmental awareness, lightweight energy-efficient hollow concrete blocks which can be recycled are increasingly used in building construction projects.

In addition, urbanization and population growth are the causes of the demand for cost-effective housing which subsequently increasing the market share for the hollow concrete blocks. They are popular for both their cost-efficiency and simplicity of setting them up on a large scale level. Therefore, they are ideal for residential and commercial buildups.

In the area of design and innovation, the hollow concrete block market is seeing the development of product innovation. The manufacturers are already oriented towards the development of blocks that are advanced structurally, have insulation and aesthetic properties. These innovations not only meet the ever changing needs of architects and builders but also contribute to overall efficiency and sustainability in construction/building projects.

The other noteworthy aspect is the growing affinity for lightweight building materials in construction. Lightweight hollow concrete blocks due to their lower weight compared to concrete blocks have an advantage in transportation and installation and thus minimize the construction time and expenditures. Such a tendency corresponds with the industry's tendency towards optimization of time and cost reduction in project realizations.

The Digital Revolution is also investing in the hollow concrete block industry, with the application of technology in manufacturing procedures. The precision and quality of mining have been improved due to the introduction of automated production lines and advanced machinery that are used. This is not only about the improvement of the quality of the blocks but also increasing the production capacity thus meeting the current demand in the market.

The global economy is one of the leading factors that are driving market trends. Tumbling of raw material prices like cement and aggregates leads directly to cost of production hike of hollow concrete blocks. Therefore, the businesses are closely monitoring these economic indicators to have them as a basis for devising the pricing strategies and production levels.

The production of hollow concrete block is region-specific owing to the geographical and social economic variables. In the developing countries, populace demand is driven by the fast urbanization and the infrastructure development while in the mature markets slowly, the focus shifts into refurbishment and sustainable construction practices. Comprehension of such local dynamics will play a crucial role for enterprises who want to make the most of the emerging possibilities.

Leave a Comment