Top Industry Leaders in the High Performance Epoxy Market

High-performance epoxies are the unsung heroes of modern technology, silently holding together critical components in aerospace, electronics, and more. this sticky market is a beehive of activity, buzzing with competition and innovation.

High-performance epoxies are the unsung heroes of modern technology, silently holding together critical components in aerospace, electronics, and more. this sticky market is a beehive of activity, buzzing with competition and innovation.

The Titans and their Grip:

Global Giants: Behemoths like Hexcel, Huntsman Corporation, and Solvay wield immense power through their extensive R&D capabilities, diverse product portfolios, and established presence in high-growth sectors. Hexcel, for instance, leverages its expertise in aerospace composites to offer high-performance epoxies for demanding applications.

Regional Champions: Players like Atul Ltd (India) and Gougeon Brothers, Inc (US) excel in specific regions due to their localized knowledge, regulatory expertise, and proximity to crucial resources. Atul Ltd caters to the burgeoning demand for high-performance epoxies in the Indian construction and electronics sectors.Niche Innovators: Smaller companies like Arkema and Momentive Performance Materials specialize in unique epoxy formulations for demanding applications like electronic encapsulation and advanced composites. Arkema's expertise in fluorinated epoxies positions them as a preferred supplier for semiconductor packaging.

Strategies that Secure a Firm Hold:

-

Product Diversification: Offering a comprehensive range of epoxies with varying properties, curing times, and temperature resistance attracts diverse customers. Huntsman Corporation caters to aerospace, wind energy, and construction sectors with its varied epoxy offerings.

-

R&D Prowess: Continuous innovation in epoxy formulations, curing technologies, and sustainable solutions is crucial for market leadership. Solvay's focus on bio-based and recyclable epoxies exemplifies this commitment.

-

Vertical Integration: Controlling the entire epoxy value chain from raw materials to finished products offers cost advantages and flexibility. Momentive Performance Materials' control over epoxy resin production gives them an edge in cost control.

-

Sustainability Focus: Addressing environmental concerns with bio-based or low-VOC epoxies aligns with customer preferences and regulatory compliance. Arkema's development of low-VOC epoxies for electronics applications demonstrates this trend.

-

Strategic Partnerships and Acquisitions: Collaborations with industry leaders, research institutions, and startups can accelerate innovation and market reach. Hexcel's partnership with a leading aerospace company on development of new epoxy-based composite materials is a prime example.

Factors Dictating Market Share Winners:

-

Aerospace Boom: Rising demand for lightweight, fuel-efficient aircraft fuels the use of high-performance epoxies in composite structures. Hexcel and Solvay are well-positioned to benefit from this trend.

-

Electronics Miniaturization: The quest for smaller, faster electronic devices drives demand for high-performance epoxies with excellent thermal and electrical properties. Arkema and Momentive Performance Materials are at the forefront of this revolution.

-

Renewable Energy Expansion: The growth of wind turbine technology and its increasing size necessitates the use of strong, weather-resistant epoxies for blade bonding. Huntsman Corporation is a leader in this segment with its specialized wind turbine epoxies.

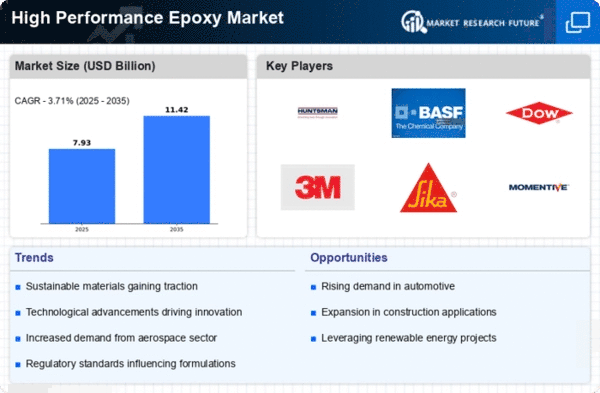

Key Players

Atul Ltd (India)The Euclid Chemical Company (US)Stentor Enterprises Limited (Kenya)Aditya Birla Group (India)Huntsman Corporation (US)Endura Manufacturing Company Ltd (US)Gougeon Brothers Inc (US)and Alchemie Ltd (UK).

Recent Developments:

-

August 2023: Henkel launches a new bio-based epoxy resin with improved fire resistance, targeting sustainable construction applications. -

September 2023: Huntsman Corporation announces a capacity expansion for its high-performance epoxy resins in China, catering to the growing Asian market. -

October 2023: BASF and SGL Carbon partner to develop carbon fiber-reinforced composites for lightweight automotive applications. -

November 2023: Dow Chemical introduces a new waterborne epoxy for electronics applications, reducing VOC emissions and environmental impact.