Glass Filled Peek Size

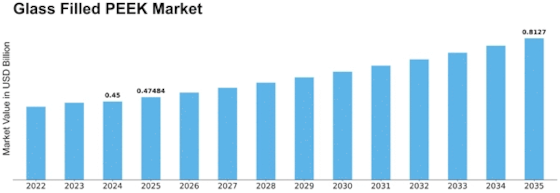

Glass Filled PEEK Market Growth Projections and Opportunities

The Glass-Filled PEEK Market is shaped by a multitude of market factors contributing to its growth and dynamics. A significant driver is the increasing demand for high-performance polymers in various industries, particularly in applications that require a combination of exceptional mechanical properties, chemical resistance, and thermal stability. Glass-filled PEEK (Polyetheretherketone) is a reinforced polymer that incorporates glass fibers into the PEEK matrix, enhancing its overall strength and stiffness. The material finds extensive use in aerospace, automotive, electronics, and medical applications, where the need for lightweight, durable, and dimensionally stable components is critical.

Technological advancements in polymer compounding and processing contribute significantly to market dynamics. Continuous research and development efforts focus on improving the dispersion of glass fibers within the PEEK matrix, optimizing the manufacturing processes, and enhancing the overall performance of glass-filled PEEK. Innovations in compounding technologies, fiber treatments, and molding techniques aim to achieve better mechanical properties and consistency in the material, expanding its applications across various industries. Technological advancements drive the adoption of glass-filled PEEK as a versatile and high-performance engineering polymer.

The aerospace and automotive industries play a pivotal role in driving the Glass-Filled PEEK Market. In aerospace applications, the material is utilized in components such as bearings, seals, and structural parts due to its lightweight nature, excellent chemical resistance, and ability to withstand high temperatures. In the automotive sector, glass-filled PEEK is increasingly used in various under-the-hood components, electrical connectors, and interior applications where a balance of mechanical strength and thermal stability is essential. The demand from these key industries contributes significantly to the growth of the glass-filled PEEK market.

Global economic conditions and trade dynamics impact the Glass-Filled PEEK Market. As a globally traded commodity, factors such as international trade agreements, tariffs, and geopolitical events can influence the supply chain and market conditions for glass-filled PEEK. Economic stability, manufacturing trends, and trade policies play a role in determining the accessibility and cost competitiveness of glass-filled PEEK materials in the market.

Environmental considerations and regulatory standards also play a role in shaping the glass-filled PEEK market. The material's chemical resistance and stability contribute to its acceptance in applications where stringent environmental regulations must be met. Compliance with environmental standards ensures that the production and use of glass-filled PEEK adhere to the highest levels of safety and sustainability. The industry's commitment to environmentally responsible practices adds to the material's appeal in various sectors.

Market competition and industry collaborations are notable factors shaping the Glass-Filled PEEK Market. The market comprises established polymer manufacturers, compounders, and end-users, fostering a competitive landscape. Collaboration between glass-filled PEEK producers, end-users, and research institutions facilitates the development of new formulations, applications, and processing techniques. Partnerships within the industry supply chain contribute to the overall growth and advancement of glass-filled PEEK solutions.

Challenges related to cost considerations, material processing complexity, and competition from alternative materials are factors that the glass-filled PEEK industry addresses. While glass-filled PEEK offers exceptional properties, including high-temperature resistance and mechanical strength, the cost of production can be higher compared to other polymers. The industry continuously works on optimizing manufacturing processes and exploring cost-effective solutions. Additionally, the complexity of processing glass-filled PEEK presents challenges in achieving uniform fiber dispersion and maintaining consistent material properties. The industry's focus on addressing these challenges contributes to the ongoing success of glass-filled PEEK in demanding applications.

Leave a Comment