Top Industry Leaders in the Geothermal Drill Bits Market

*Disclaimer: List of key companies in no particular order

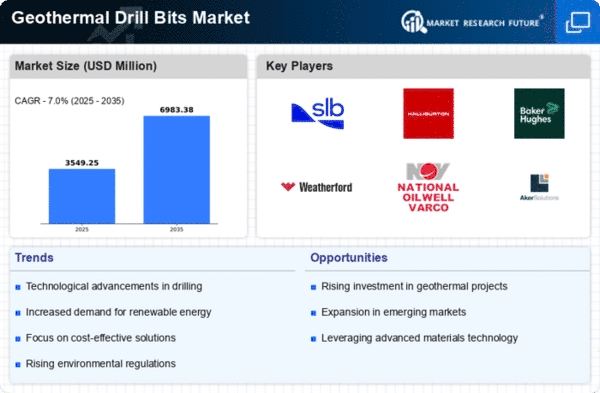

Top listed companies in the Geothermal Drill Bits industry are:

Baker Hughes Co. (US)

America West Drilling Supply Inc. (US)

Epiroc AB (Sweden)

Halliburton (US)

Torquato Drilling Accessories (US)

National Oilwell Varco (US)

Varel International Energy Services (US)

Schlumberger Ltd. (US)

Weatherford International plc (US)

Bit Brokers International Ltd. (US)

Key Players and Strategies:

Dominating the market are established giants like Baker Hughes, Halliburton, and Schlumberger. These players leverage their extensive experience in oil and gas drilling technology, adapting and optimizing it for geothermal applications. Their global reach, diverse product portfolios including polycrystalline diamond compact (PDC) and tricone bits, and strong distribution networks provide them with a distinct edge.

Smaller players like Boart Longyear, Smith International, and Newtek Drilling Technologies are carving their own niches. Boart Longyear focuses on innovative cutting structures and materials, while Smith International emphasizes customized solutions for complex geothermal formations. Newtek Drilling Technologies, with its cost-effective PDC bits, targets budget-conscious projects.

Collaboration and strategic partnerships are becoming increasingly common. Schlumberger partnered with Icelandic Geothermal Drilling Solutions to develop advanced geothermal drilling tools. Baker Hughes, on the other hand, collaborated with a research institute to design PDC bits specifically for hot, hard rock formations.

Factors for Market Share Analysis:

Market share analysis in the geothermal drill bits market depends on several key factors. Regional demand plays a significant role, with North America currently leading the pack due to supportive government policies and a mature geothermal industry. Asia Pacific and Europe are witnessing rapid growth, driven by ambitious clean energy targets.

Technological advancements influence market share as well. Companies with a strong R&D focus and innovative product offerings, like PDC bits with enhanced thermal stability and wear resistance, gain a competitive edge. Additionally, expertise in downhole data analysis and real-time performance monitoring attracts customers seeking efficient drilling operations.

Customer service and after-sales support are crucial differentiators. Players with robust field service networks and readily available spare parts win the trust of drilling contractors, especially in remote geothermal locations. Furthermore, sustainability initiatives, such as reducing water usage and minimizing environmental impact, resonate with environmentally conscious clients.

New and Emerging Trends:

The geothermal drill bits market is witnessing several exciting trends. Automation and digitalization are gaining traction, with companies developing smart bits equipped with sensors that provide real-time data on formation characteristics and drilling performance. This data helps optimize drilling parameters, maximizing efficiency and reducing downtime.

Renewable energy developers are increasingly interested in enhanced geothermal systems (EGS), which involve stimulating underground heat resources. This necessitates specialized drill bits capable of withstanding high temperatures and pressures in fractured rock formations. Players are actively developing and testing EGS-specific drill bit designs.

Another emerging trend is the growing focus on cost-effectiveness. Drill bit manufacturers are exploring alternative materials and production processes to bring down costs without compromising performance. This is particularly relevant for cost-sensitive projects in developing countries.

Overall Competitive Scenario:

The geothermal drill bits market is expected to grow steadily in the coming years, driven by the global push for renewable energy. The competition is intense, with established players leveraging their experience and resources while smaller companies seek differentiation through innovation and niche expertise. Collaboration, technological advancements, and a focus on cost-effectiveness and sustainability will be key factors shaping the competitive landscape in the years to come.

Latest Company Updates:

Epiroc AB (Sweden):

• April 2023: Opened a new heat treatment facility for rock drills, improving drill bit quality and performance. (Source: Epiroc press release, April 2023)

National Oilwell Varco (US):

• April 2023: Introduced Phoenix Series Drill Bits with improved thermal and abrasion resistance for harsh geothermal environments. (Source: National Oilwell Varco website)