- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

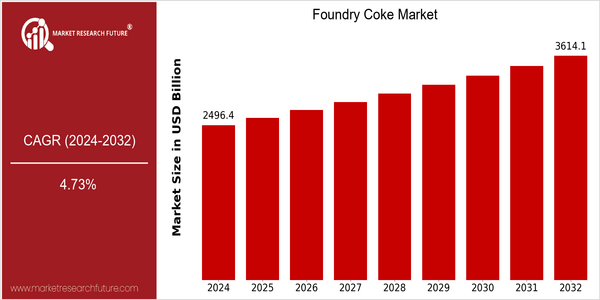

| Year | Value |

|---|---|

| 2024 | USD 2496.42 Billion |

| 2032 | USD 3614.07 Billion |

| CAGR (2024-2032) | 4.73 % |

Note – Market size depicts the revenue generated over the financial year

The market for coke for foundries is likely to increase from $ 2496.4 million in 2024 to $ 3614.07 million by 2032. Its annual growth rate is 4.73% over the forecast period from 2024 to 2032. This growth is due to the increased demand for coke for foundries, which is mainly due to the indispensable role of coke in the production of iron and steel. The modernization and development of industry will also increase the demand for coke for foundries. Technological progress in production and the growing importance of environment also have an effect on the market. In the process of coke production, innovations are more and more focused on increasing the efficiency of coke production and reducing the negative impact of coke production on the environment. The main trends in this market are ArcelorMittal and China National Coal Group. ArcelorMittal is investing in the latest clean coal technology, while China National Coal Group is focusing on the development of its supply chain. These trends not only meet the needs of the world's sustainable development, but also make these companies more competitive in the market. , to meet the needs of the market.

Regional Market Size

Regional Deep Dive

Casting-coke has been characterized by its critical role in the metallurgical industry, particularly in the production of iron and steel. Each region has its own characteristics, influenced by local industrial needs, regulations, and economic conditions. In North America, the market is driven by a thriving manufacturing sector and increasing investment in public works. Europe focuses on the green economy and innovation, while Asia-Pacific is experiencing the effects of rapid urbanization and industrialization, which has increased demand. Middle East and Africa are promising growth markets with strong potential for expansion due to increasing industrial activity, and Latin America is boosting its production capacities by taking advantage of its abundant natural resources.

Europe

- In Europe, the foundry coke market is heavily influenced by the European Union's Green Deal, which aims to make the region climate-neutral by 2050, pushing companies to adopt more eco-friendly practices.

- Key players like ArcelorMittal are investing in research and development to create alternative materials that can replace traditional foundry coke, reflecting a significant trend towards sustainability in the region.

Asia Pacific

- Asia-Pacific is witnessing a surge in demand for foundry coke due to rapid industrialization, particularly in countries like China and India, where major companies such as China National Coal Group are expanding production capacities.

- Government initiatives in India, such as the Make in India program, are boosting the manufacturing sector, thereby increasing the demand for foundry coke as a critical input in steel production.

Latin America

- Latin America is leveraging its abundant natural resources, with countries like Brazil and Argentina ramping up foundry coke production to meet both domestic and export demands.

- The region is also witnessing collaborations between local companies and international firms to enhance production technologies, which is expected to improve the quality and efficiency of foundry coke.

North America

- The North American foundry coke market is experiencing a shift towards more sustainable production methods, with companies like SunCoke Energy investing in cleaner technologies to reduce emissions.

- The regulating authorities, especially in the United States, in the matter of the emission of carbon, are compelling the producers of coke for the foundry to make modifications and to adopt new methods.

Middle East And Africa

- The Middle East and Africa are seeing increased investments in the foundry coke market, with countries like South Africa focusing on enhancing their metallurgical capabilities to support local industries.

- Regulatory frameworks in the region are evolving, with governments encouraging local production of foundry coke to reduce dependency on imports, which is expected to stimulate market growth.

Did You Know?

“Did you know that foundry coke is not only used in iron and steel production but also plays a crucial role in the manufacturing of aluminum and other non-ferrous metals?” — International Journal of Metallurgical Engineering

Segmental Market Size

The Foundry Coke Market is a critical part of the metallurgical sector, which mainly serves the iron and steel industry. This market is currently experiencing stable growth, driven by the increasing demand for high-quality coke in the production of steel. The resurgence of the construction industry and the growing production of steel in emerging economies, particularly in the Asia-Pacific region, especially in China and India, are the main reasons for this growth. The Foundry Coke Market is in its maturity phase, with the leading companies such as ArcelorMittal and Tata Steel leading the production and innovation. The main application of foundry coke is in the reduction of iron ore in blast furnaces and as a reducing agent in various metallurgical processes. Among the most important trends affecting this market are the efforts to reduce carbon emissions, which are pushing companies to use other materials and production methods. Also, the development of carbon capture and storage (CCS) is a major trend affecting the market, as industries seek to meet stricter regulations while maintaining their competitiveness.

Future Outlook

The Coke Market for Foundry Use is set to grow at a CAGR of 4.7% from 2024 to 2032, from $2,496,421 million to $3,614,070 million. The market is characterized by the increasing demand for high-quality foundry coke in the iron and steel industry, driven by the ongoing industrialization of emerging economies and the increasing need for efficient and sustainable production processes. The implementation of new production methods and the use of advanced coke-making technology are expected to further stimulate the market. Moreover, the introduction of stricter environmental regulations and the increasing use of cleaner production methods will have a positive impact on the future of the foundry coke market. In particular, the implementation of carbon emissions regulations is expected to encourage foundry operators to invest in new coke-making technology to increase the efficiency of coke production and reduce the negative impact on the environment. The growing trend towards the use of alternative materials and the growing use of recycled materials in foundries will also have a positive effect on the market. Consequently, the penetration of foundry coke will continue to increase, and quality and performance will become more important, which will make it an indispensable component of future foundry and metalworking processes.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 2.94 Billion |

| Growth Rate | 4.35% (2024-2032) |

Foundry Coke Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.