Market Trends

Key Emerging Trends in the Food Tray Sealing Machines Market

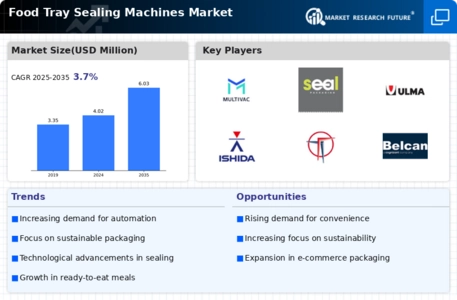

The market trends of food tray sealing machines are undergoing significant changes influenced by advancements in food packaging technology, consumer demands for convenience, and the growing focus on sustainability. One notable trend in this market is the increasing demand for efficient and automated tray sealing solutions. As the food industry strives for higher production speeds and enhanced hygiene standards, food tray sealing machines equipped with automation features, including robotic handling and intelligent control systems, are gaining popularity. These machines not only improve efficiency but also contribute to maintaining product quality and safety.

Moreover, sustainability is a key influencer in the food tray sealing machine market. With heightened awareness of environmental issues, there is a growing demand for packaging solutions that reduce waste. Manufacturers are responding by developing tray sealing machines that use eco-friendly materials and support the use of recyclable or compostable trays. This trend aligns with the broader industry push towards sustainable practices, meeting consumer preferences for more environmentally responsible packaging solutions.

Customization is emerging as another significant trend in the food tray sealing machine market. As consumer preferences for diverse and personalized food options increase, manufacturers are offering machines that can accommodate various tray sizes, shapes, and sealing configurations. Customizable features not only cater to the visual appeal of packaged food but also address the demand for flexible packaging solutions that can adapt to a wide range of food products.

Technological advancements are playing a crucial role in reshaping the food tray sealing machine market. Manufacturers are incorporating intelligent sensors, vision systems, and real-time monitoring capabilities into their machines. These technological features enable precise control over the sealing process, ensuring consistent quality and reducing the likelihood of errors. Additionally, the integration of smart technologies allows for real-time data analysis, predictive maintenance, and remote monitoring, contributing to overall operational efficiency.

Furthermore, there is a growing trend towards modified atmosphere packaging (MAP) and vacuum skin packaging (VSP) in the food tray sealing machine market. These packaging technologies extend the shelf life of perishable food products by controlling the atmosphere within the sealed tray. MAP helps retain freshness by adjusting gas compositions, while VSP provides a tight, transparent seal directly against the product, enhancing product visibility and presentation. These advanced packaging techniques respond to consumer demands for longer-lasting, visually appealing, and minimally processed food options.

E-commerce is influencing market trends in the food tray sealing machine sector. With the rise of online grocery shopping and food delivery services, there is an increased need for packaging that ensures the safe transportation of food trays. Sealed trays not only protect food products from contamination during transit but also contribute to improved food safety. The adaptability of food tray sealing machines to various tray sizes and packaging configurations makes them suitable for the diverse needs of the e-commerce food industry.

In terms of market dynamics, competition among food tray sealing machine manufacturers is intensifying. Companies are investing in research and development to enhance the automation, sustainability, and technological features of their machines. Meeting regulatory standards for food safety, reducing packaging waste, and addressing the specific needs of the food industry are critical factors for success in this competitive market. As consumer preferences and industry regulations continue to evolve, the food tray sealing machine market is expected to witness further innovation and growth.

Leave a Comment