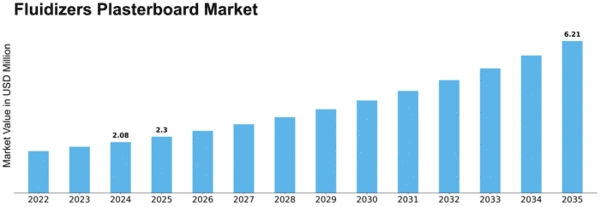

Fluidizers Plasterboard Size

Fluidizers Plasterboard Market Growth Projections and Opportunities

In the plasterboard business, fluidizers shape its elements. Fluidizers improve stream characteristics and are essential for plasterboard production because they ensure gypsum slurry consistency and functionality. The growing need for high-quality development materials affects plasterboard fluidizer use.

Continuous progress in the development area increases the need for cutting-edge building materials with improved performance and durability. Fluidizers help make high-quality plasterboard by ensuring a smooth gypsum slurry flow during assembly. This leads to plasterboard with improved dependability and surface finish that meets manufacturer and end-user expectations.

Key market factors include supportability and ecological considerations. Plasterboard manufacturers are under pressure to use eco-friendly materials and processes as green development practices become more important. Fluidizers can boost plasterboard production and reduce waste if used wisely. This aligns with the global trend toward practical development, making fluidizers crucial to the market's environmental response.

Plasterboard fluidizer use is driven by market seriousness. Organizations strive to improve their assembly processes to gain an edge. Fluidizers boost production and asset efficiency, improving functional competency. Trying to meet the growing demand for plasterboard while staying cost-effective becomes increasingly important.

In addition, mechanical headways shape the plasterboard industry. Innovating fluidizer definitions and application procedures can greatly impact plasterboard production. To stay ahead, manufacturers are enthusiastic to adopt future developments, and fluidizers address a critical area where advances can improve product quality and production efficiency.

Fluidizer use in the plasterboard industry is also affected by market standards. To ensure safety, quality, and sustainability, governments regulate development materials. Plasterboard fluidizer consolidation should follow these standards, forcing manufactures to use definitions that exceed administrative requirements. Compliance with these principles is a market requirement and a strategy for companies to build customer trust.

The plasterboard market depends on several aspects, and fluidizers are crucial to understanding them. Interest in outstanding development materials, maintainability concerns, market seriousness, mechanical advances, and administrative principles shape the plasterboard fluidizer industry. As the development sector grows, fluidizers are critical for producers attempting to meet market needs and stay ahead in this powerful industry.

Leave a Comment