Market Analysis

In-depth Analysis of Ethyleneamines Market Industry Landscape

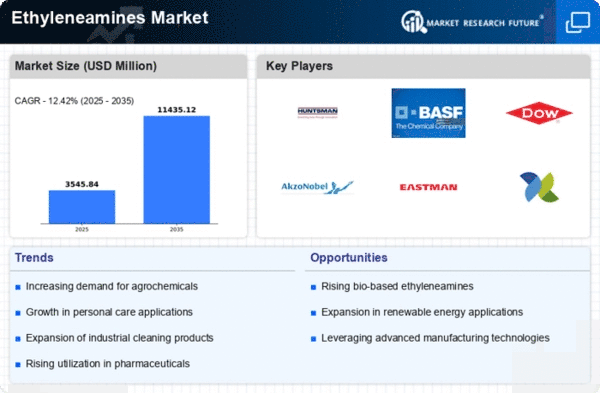

The ethyleneamines market is characterized by dynamic factors that influence supply, demand, and pricing within the industry. Ethyleneamines are versatile chemicals used in a wide range of applications including adhesives, resins, detergents, and personal care products. The market dynamics of ethyleneamines are shaped by several key factors including raw material prices, demand from end-use industries, regulatory factors, and technological advancements.

The Korean automotive industry is witnessing significant changes and offers new lightweight and high-performance polyurethane system solutions opportunities. The latest joint venture will boost growth in this sector by offering sustainable innovations and a high level of technical service support to its customers.

One of the primary drivers of market dynamics in the ethyleneamines industry is the demand from various end-use sectors. Industries such as automotive, construction, and agriculture rely on ethyleneamines for applications such as lubricant additives, corrosion inhibitors, and crop protection chemicals. As these industries experience fluctuations in demand due to economic conditions, seasonal variations, and other factors, the demand for ethyleneamines also fluctuates accordingly.

Raw material prices play a significant role in determining the overall cost structure of ethyleneamines production. Ethyleneamines are primarily derived from ethylene oxide and ammonia, both of which are petrochemical derivatives. Therefore, changes in crude oil prices and natural gas prices directly impact the production cost of ethyleneamines. Fluctuations in raw material prices can affect the profitability of ethyleneamines manufacturers and influence pricing strategies in the market.

Regulatory factors also influence the dynamics of the ethyleneamines market. Ethyleneamines are subject to regulations related to environmental, health, and safety standards in various regions around the world. Regulatory changes can impact the production processes, product specifications, and market access for ethyleneamines manufacturers. Compliance with regulations often requires investments in technology, research, and development, which can affect the cost structure and competitiveness of ethyleneamines products.

Technological advancements play a crucial role in shaping the competitive landscape of the ethyleneamines market. Innovations in production processes, catalysts, and product formulations can lead to cost reductions, product differentiation, and improved performance characteristics. Companies that invest in research and development to develop new technologies or improve existing ones can gain a competitive advantage in the market. Additionally, technological advancements may enable the development of novel applications for ethyleneamines, expanding the potential market opportunities.

Market dynamics in the ethyleneamines industry are also influenced by factors such as supply chain disruptions, geopolitical events, and currency fluctuations. Disruptions in the supply chain, such as natural disasters or transportation issues, can lead to temporary shortages or disruptions in ethyleneamines availability. Geopolitical events, such as trade tensions or conflicts in key producing regions, can also impact market dynamics by affecting supply routes or trade agreements. Currency fluctuations can affect the competitiveness of ethyleneamines manufacturers operating in different regions by impacting import/export costs and pricing competitiveness.

Overall, the ethyleneamines market is characterized by dynamic factors that influence supply, demand, and pricing within the industry. Understanding these market dynamics is essential for stakeholders, including producers, suppliers, distributors, and end-users, to make informed decisions and navigate the complexities of the ethyleneamines market. By closely monitoring trends in raw material prices, demand from end-use industries, regulatory developments, technological advancements, and other factors, stakeholders can effectively manage risks and capitalize on opportunities in the ethyleneamines market.

Leave a Comment