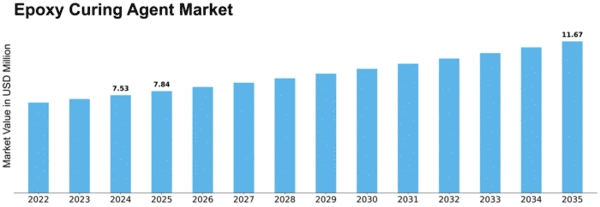

Epoxy Curing Agent Size

Epoxy Curing Agent Market Growth Projections and Opportunities

The Epoxy Curing Agent market is influenced by various market factors that collectively shape its growth and dynamics. One of the primary drivers is the widespread application of epoxy curing agents in the coatings, adhesives, and composites industries. As epoxy resins continue to be a preferred choice for their excellent mechanical properties and versatility, the demand for curing agents to enhance their performance and durability remains robust. Industries such as construction, automotive, electronics, and aerospace rely heavily on epoxy curing agents to provide strength, adhesion, and chemical resistance to various materials.

Technological advancements play a crucial role in the evolution of the Epoxy Curing Agent market. Continuous research and development efforts focus on creating innovative curing agents with improved curing speed, thermal stability, and environmental compatibility. The development of low-temperature curing agents, bio-based alternatives, and formulations with reduced volatile organic compounds (VOCs) addresses both performance and environmental concerns, influencing the market landscape. The adoption of advanced curing technologies, such as UV curing agents, also contributes to the market's growth by providing faster and energy-efficient curing solutions.

Market dynamics are significantly influenced by the growth and trends in end-use industries. For instance, the construction industry's demand for high-performance adhesives and coatings contributes to the increased use of epoxy curing agents. In the electronics sector, where miniaturization and reliability are paramount, epoxy resins with advanced curing agents find application in encapsulation and electronic packaging. Understanding and aligning with the specific needs and trends in these end-use industries are crucial for epoxy curing agent manufacturers to stay competitive in the market.

Global environmental regulations and sustainability considerations are increasingly shaping the Epoxy Curing Agent market. Governments worldwide are implementing stringent regulations to reduce emissions and promote the use of environmentally friendly products. This has led to the development of water-based and solvent-free curing agents with lower environmental impact. Compliance with these regulations not only ensures market acceptance but also positions companies favorably in an industry where sustainability is becoming a key differentiator.

Raw material availability and pricing dynamics play a significant role in the Epoxy Curing Agent market. Key ingredients in curing agents, such as amines and acids, are derived from various sources. Fluctuations in the prices of these raw materials can impact production costs, influencing market prices. Maintaining a stable and secure supply chain for raw materials becomes essential for manufacturers to ensure consistency in product quality and pricing.

Market competition is another pivotal factor influencing the Epoxy Curing Agent sector. Intense competition among manufacturers drives continuous innovation and the development of new formulations. Companies strive to differentiate their products by focusing on factors such as curing efficiency, compatibility with different epoxy resins, and customization options. Strategic collaborations, partnerships, and mergers and acquisitions are common strategies employed by companies to strengthen their market position, expand their product portfolios, and capitalize on emerging opportunities.

Consumer preferences and market trends also contribute to the shaping of the Epoxy Curing Agent market. The increasing demand for high-performance, sustainable, and easy-to-use curing agents reflects the evolving preferences of end-users. Additionally, trends in product design, such as the use of lightweight materials and the growing importance of 3D printing, influence the development of epoxy curing agents with specific characteristics to meet these emerging needs.

Leave a Comment