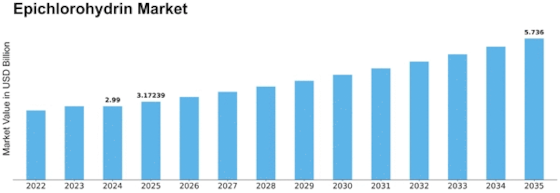

Epichlorohydrin Size

Epichlorohydrin Market Growth Projections and Opportunities

The dynamics of the Epichlorohydrin Market are influenced by different factors. Epoxy resins, synthetic glycerol and water treatment chemicals are some of the products made from epichlorohydrin. The demand for these products in industries is therefore very crucial as it affects the growth of the whole industry as well as that of other market players. Epoxy resins are one of the major applications for epichlorohydrin, which has been a driving force behind industrial demand. Epoxy resins made from epichlorohydrin find application in coatings, adhesives, electrical laminates and many others. As construction, automotive and electronic sectors continue growing so does demand for epoxy resins and subsequently, epichlorohydrin. The versatility of epoxy resin in improving product performance leads to sustained high demand for Epichlorohydrin. Regulatory compliance is another crucial factor shaping this particular market. For instance, production and use activities are guided by strict environmental and safety policies on using epichlorohydrin that influence manufacturing processes as well as overall application protocols. Therefore industry players have to embrace eco-friendly practices aimed at reducing emissions while ensuring safe production process in order to comply with such regulations set forth. How this sector responds to ever changing standards of regulatory framework contributes to its sustainability regarding ecological issues. Raw material availability accounts for how much propylene is used to produce Epichlorohydrine hence affecting it’s total cost price. Changes in petrochemical structure affect the markets responsiveness through raw material considerations especially when there are fluctuations in propylene supply/ price which eventually change overall costs of production hence making it vital aspect of market dynamics The development of alternative feedstocks and production methods is a strategic focus for industry participants seeking solutions related to raw materials challenges. Market dynamics also result from technological advancements taking place within the process of producing epichlorohydrin. These include research and development endeavours that aim at improving efficiency, reducing energy consumption, and improving environmental performance. Being a critical aspect in enhancing sustainability and decreasing cost effectiveness of Epichlorohydrine production, catalytic technology innovations and process optimization have been made possible. For industry players to stay relevant in this market, advanced technologies are crucial.

Leave a Comment