- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

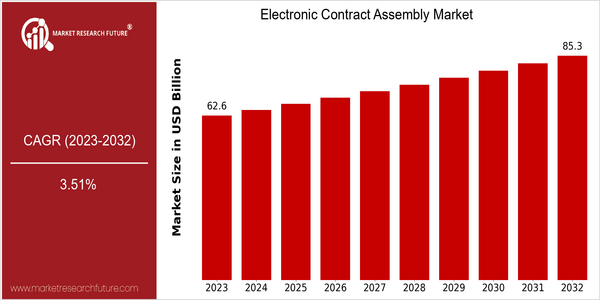

| Year | Value |

|---|---|

| 2023 | USD 62.56 Billion |

| 2032 | USD 85.3 Billion |

| CAGR (2024-2032) | 3.51 % |

Note – Market size depicts the revenue generated over the financial year

E-Cabling market will reach $63 billion in 2023 and is expected to reach $85 billion by 2032, at a CAGR of 3.51%. This growth rate is due to the growing complexity of electrical and electronic devices and the need for effective manufacturing processes. Industry is continuing to adopt automation and advanced manufacturing. Several factors are contributing to this upward trend, such as the increasing use of IoT devices, the development of automation technology and the need to reduce production costs while maintaining high quality standards. These factors will increase the market share of major players such as Flex, Jabil and Celestica. The development of new collaborations such as artificial intelligence and machine learning will further optimize the manufacturing process and increase efficiency, thereby contributing to the growth of the market.

Regional Market Size

Regional Deep Dive

The Electronics Contract Assembly Market is growing strongly across many regions, driven by the increasing demand for electronic components in the automotive, consumer goods, and telecommunications industries. North America has a strong market presence and is characterized by innovation, while Europe focuses on the importance of compliance with regulatory requirements and the environment. The Asia-Pacific region is experiencing rapid growth due to its manufacturing capabilities and cost advantages. Meanwhile, the Middle East and Africa are slowly becoming new market regions, thanks to government initiatives to promote local industry. Latin America is also experiencing moderate growth, but is struggling to overcome the economic crisis and to attract foreign investors.

Europe

- The European Union's Green Deal has spurred innovation in sustainable electronics, with companies like Siemens and STMicroelectronics investing in eco-friendly manufacturing processes for contract assembly.

- Regulatory frameworks such as the RoHS and WEEE directives are pushing contract assembly firms to adopt more sustainable practices, which is reshaping the competitive landscape in the region.

Asia Pacific

- China continues to dominate the electronic contract assembly market, with companies like Foxconn and Pegatron expanding their capabilities to meet the rising demand for consumer electronics and IoT devices.

- The Indian government’s 'Make in India' initiative is attracting foreign investment in electronics manufacturing, leading to a surge in local contract assembly firms and partnerships with global players.

Latin America

- Brazil is emerging as a hub for electronic contract assembly, with government incentives aimed at boosting local production and attracting foreign investment from companies like Flextronics.

- The region is witnessing a trend towards nearshoring, as companies seek to reduce supply chain risks by relocating assembly operations closer to North American markets.

North America

- The rise of electric vehicles (EVs) has led to increased demand for electronic components, prompting companies like Flex and Jabil to expand their contract assembly services to cater to this growing market.

- Recent regulatory changes in the U.S. aimed at enhancing supply chain resilience have encouraged local sourcing of electronic components, benefiting contract assembly firms that can provide quick turnaround times.

Middle East And Africa

- Countries like the UAE are investing heavily in technology parks and free zones to attract electronic manufacturing and assembly firms, with companies like Emirates Global Aluminium diversifying into electronics.

- Government programs aimed at enhancing local manufacturing capabilities are encouraging partnerships between local firms and international contract assembly companies, fostering growth in the region.

Did You Know?

“Did you know that the electronic contract assembly market is projected to see a significant shift towards automation, with companies increasingly adopting robotics and AI technologies to enhance efficiency and reduce costs?” — Industry reports and market analysis from credible sources such as Gartner and IDC.

Segmental Market Size

The market for electronic contract manufacturing is a vibrant and critical part of the overall electronics manufacturing industry. It is presently growing as a result of an increasing demand for customized electronic products. The need for rapid technological development and the increasing cost of raw materials are the principal forces driving this market. Furthermore, regulations that promote the localization of production and the reduction of emissions are also encouraging the use of contract manufacturing services. Consequently, the contract manufacturing market has reached a mature stage of development, with the two leading companies, Jabil and Flextronics, being based in North America and Asia. The main applications of contract manufacturing are in the fields of consumer electronics, automobiles, and medical devices, where precision and speed are of paramount importance. The increasing demand for sustainability and the increasing disruption to the global supply chain are also fostering this growth, as companies are seeking reliable partners for their contract manufacturing needs. The development of automation, the integration of the Internet of Things, and the implementation of advanced quality control methods are also promoting the evolution of this market, ensuring that it is able to meet industry standards.

Future Outlook

From 2023 to 2032, the market for electronic contract manufacturing is expected to increase from $ 62.5 billion to $ 85 billion, with a compound annual growth rate of 3.17%. This growth is based on the increasing demand for smart electronic components in the fields of automobiles, household appliances, and health care. The market penetration rate of contract manufacturing will also increase as the automation level of various industries increases. Emerging markets will see a penetration rate of about 25% by 2032, as local manufacturers will also seek to improve their production capabilities through out-of-house collaboration. Artificial intelligence and machine learning in the process of assembling and dismantling will also improve the efficiency of the production process and reduce the cost of production. Also, as the emphasis on sustainable development and the environment increases, contract manufacturers will be forced to use more green and environmentally friendly materials and technology. Also, government policies to strengthen the resilience of supply chains and reduce the dependence of single-source suppliers will also play a role in determining the trend of the market. The market for contract manufacturing will be affected by these changes. In this process, it is important to be flexible and quick to respond to opportunities and challenges.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 9.8% |

Electronic Contract Assembly Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.