Drive By Wire Size

Drive-by-wire Market Growth Projections and Opportunities

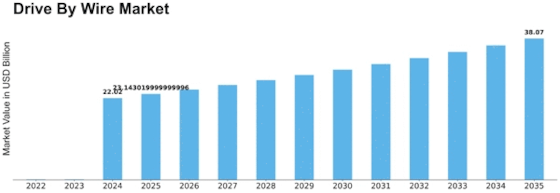

Drive By Wire market Sensor Type is predicted to rise 5.90% each year from 2023 to 2032, from USD 20.8 billion to USD 32.8 billion. The auto industry is introducing drive-by-wire technology. Thus, motorized device removal is back. This is positive since it expands automotive industry potential. This has allowed the auto industry to produce lighter, more fuel-efficient automobiles. Drive-By-Wire Market reached $24 billion worldwide in 2019. It's expected to be valued $31.9 billion by 2024, expanding 5.9% annually. Drive-By-Wire Market is a computer-controlled semi-automatic automobile gadget. It relates to electronic automobile control. Drive by wire technique controls brakes, speed, turning, handling, and engine filling via sensors and actuators. These innovations and device enhancements eliminate drive-belts, vacuum boosters, pumps, driveshafts, and other components. New technology and a demand for inventive automobile alternatives have changed the drive-by-wire industry swiftly. Mechanical connections govern turning, stopping, and speeding in typical automobiles. Drive-by-wire systems use computer controls instead of physical connections. Creating safer, more efficient, and better automobiles is the driving force behind this paradigm shift in automotive technology. The constant pursuit of safer automotive features drives the drive-by-wire business. Standard mechanical setups are difficult to match for accuracy and speed. Electronically controlled turning, stopping, and speeding allow for more sophisticated safety measures like ADAS. Drive-by-wire technologies may become more popular as automobiles become self-driving. Self-driving requires these systems. Focusing more on fuel efficiency and environmental responsibility is also affecting the drive-by-wire business. Electronic control of vehicle functions maximizes energy and fuel economy. This reduces fuel usage and supports global pollution reduction and green transportation. Drive-by-wire is needed to fulfill tough emission regulations imposed by governments worldwide. The market is also affected by electric vehicle production. Electric automobiles (EVs) are becoming increasingly prevalent, therefore drive-by-wire is virtually needed. Electric automobiles require finer control over jobs to maximize energy consumption and performance. Drive-by-wire technology lets electric power systems adapt to diverse cars. This smoothes electric drivetrains. Cost is a major component in the drive-by-wire industry. Modern technologies may cost manufacturers extra initially. As technology improves and more people use it, economies of scale should lower manufacturing costs. Cutting technical elements in automobiles may help them live longer and cost less, saving producers and buyers money over time. Drive-by-wire technology is also impacted by automobile industry partnerships. Automakers engage with specialist suppliers and tech businesses to maximize their experts' output and accelerate innovation as technology advances. These ties enable cutting-edge drive-by-wire systems for multiple manufacturers. These solutions may be employed in many motor sector applications. In conclusion, safety advancements, environmental concerns, electric vehicle sales, cost concerns, and auto industry collaboration impact the drive-by-wire system market. Drive-by-wire technology will become more important in smart and sustainable transportation. It will affect automotive design and performance in the future.

Leave a Comment