Top Industry Leaders in the Dimethylaminopropylamine Market

Dimethylaminopropylamine (DMAPA), a versatile organic compound, finds its way into everyday items like shampoos, construction materials, and even pharmaceuticals, the DMAPA landscape has morphed into a dynamic labyrinth where established giants and nimble newcomers alike vie for dominance.

Dimethylaminopropylamine (DMAPA), a versatile organic compound, finds its way into everyday items like shampoos, construction materials, and even pharmaceuticals, the DMAPA landscape has morphed into a dynamic labyrinth where established giants and nimble newcomers alike vie for dominance.

Demystifying the Strategies:

-

Product Diversification: Giants like BASF, Solvay, and Huntsman are pushing the boundaries, extending their offerings beyond traditional grades to cater to specific industry needs. BASF's focus on high-purity DMAPA for pharmaceutical applications demonstrates this shift. -

Geographical Expansion: Asia-Pacific, with its booming construction and consumer goods sectors, beckons for expansion. Solvay's 2022 acquisition of a Chinese DMAPA manufacturer exemplifies this trend. -

Vertical Integration: Gaining control over the supply chain is a cost-saving and resilience-building mantra. Companies like Hefei TNJ Chemical are investing in upstream methylamine production to secure raw material access. -

Technological Innovation: Embracing sustainability and efficiency is key. Eastman Chemical's novel continuous production process for DMAPA minimizes wastewater generation and energy consumption, setting a new benchmark. -

Strategic Partnerships: Joining forces with downstream users in key industries like epoxy resins or crop protection chemicals can solidify long-term demand and market access.

Unveiling the Secrets of Market Share:

-

Production Powerhouses: Giants like BASF hold significant sway due to their massive production capacities. However, new entrants in China are challenging this dominance with competitive pricing. -

Geographical Dynamics: Asia-Pacific currently consumes over 50% of global DMAPA, followed by North America and Europe. Regional economic fluctuations and supply chain disruptions can significantly impact market share. -

Application Diversification: While epoxy resins remain the king, growth in segments like pharmaceuticals and crop protection chemicals offers opportunities for players targeting specific niches. -

Environmental Guardians: Stringent regulations on emissions and waste disposal can increase production costs and favor companies with sustainable practices. -

Price Volatility: Raw material fluctuations and geopolitical factors can lead to price swings, impacting demand and profitability across the value chain.

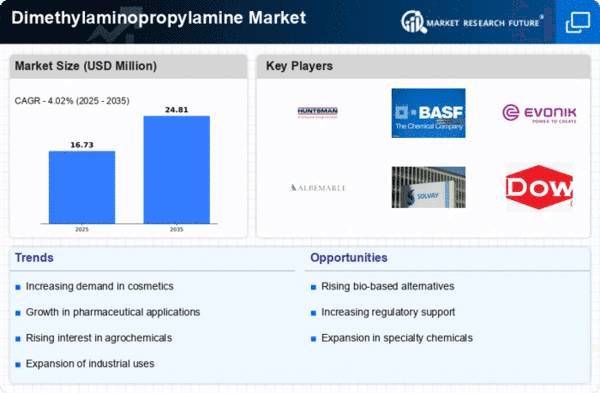

Key Players:

BASF SE (Germany), Huntsman International LLC (US), Merck KGaA (Germany), Haihang Industry Co., Ltd (China), Air Products and Chemicals, Inc. (US), Alkyl Amines Chemicals Limited (India), Solvay SA (Belgium), Tianjin Zhonxin Chemtech Co., Ltd (China), and The Chemours Company (US), Realet Chemical Technology Co. Ltd (China).

Unpacking the Recent Past:

July 2023: BASF secures a long-term supply agreement with a leading Chinese epoxy resin manufacturer, guaranteeing a stable outlet for its DMAPA production.

September 2023: A fire at a major Indian DMAPA plant disrupts supply and leads to temporary price hikes in the region.

November 2023: Solvay announces a collaboration with a renewable energy provider to power its European DMAPA plants, showcasing its commitment to sustainability.