Crushers Size

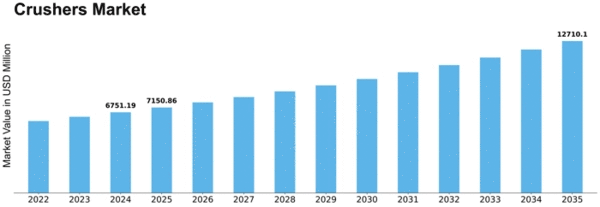

Crushers Market Growth Projections and Opportunities

The demand for crushers is increasing worldwide due to the rising need for metals and commodities, particularly driven by the growth of the mining industry. The global crusher market is expected to grow at a rate of 5.3% from 2021 to 2027. In 2020, Asia-Pacific dominated the crusher market, holding a 60.5% share, followed by North America and Europe with shares of 21.1% and 6.8%, respectively.

The global crusher market is categorized based on product type, application, and region. Product types include cone crushers, high-pressure grinding rolls, impact crushers, and jaw crushers. Among these, the cone crusher segment is projected to grow at a rate of 4.7% during the forecast period, having held a 40.1% share in the global crusher market in 2020.

Regarding applications, crushers are used for both metallic and non-metallic materials. The metallic application segment is anticipated to grow at a rate of 5.3% during the forecast period, holding a 53.4% share in the global crusher market in 2020.

The growth in the crusher market can be attributed to the increasing demand for metals and minerals, driven by various industries such as construction, mining, and infrastructure development. Crushers play a vital role in breaking down large rocks and ores into smaller, manageable pieces, facilitating the extraction and processing of valuable materials. As developing countries invest in infrastructure projects and industrialization, the demand for crushers is expected to continue its upward trajectory.

In terms of product types, cone crushers are gaining prominence due to their efficiency in crushing various materials. The ability of cone crushers to handle a wide range of materials and applications, including hard and abrasive ones, contributes to their growing popularity. Additionally, advancements in technology, such as automation and remote monitoring, enhance the operational efficiency of cone crushers, making them a preferred choice in the market. The continuous development of innovative crusher technologies is likely to drive the overall growth of the market in the coming years.

Leave a Comment