Market Trends

Key Emerging Trends in the Corrugated Polycarbonate Panels Market

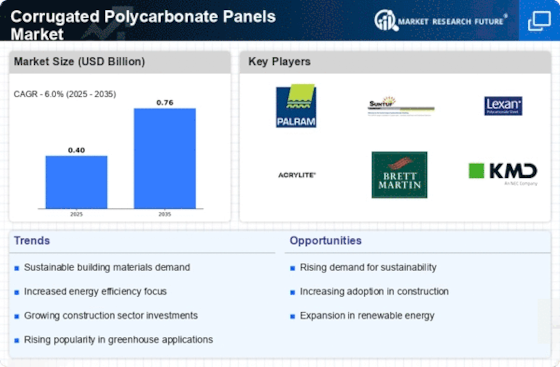

The corrugated polycarbonate panels market is experiencing notable trends that are reshaping its landscape and driving growth across various industries. One significant trend is the increasing demand for corrugated polycarbonate panels in the construction sector. Corrugated polycarbonate panels, known for their durability, impact resistance, and lightweight properties, are widely used in construction applications such as roofing, skylights, walls, and canopies. With the growing emphasis on sustainable building materials, energy efficiency, and natural light integration, the demand for high-quality corrugated polycarbonate panels is on the rise in the construction industry. Moreover, advancements in panel design, UV protection, and insulation properties are driving the adoption of corrugated polycarbonate panels in residential, commercial, and industrial construction projects.

Additionally, there is a growing trend towards the use of corrugated polycarbonate panels in the agricultural sector. Corrugated polycarbonate panels are utilized in agricultural applications such as greenhouse roofing, sidewalls, and cladding due to their light transmission, thermal insulation, and durability properties. With increasing demand for efficient and sustainable farming practices, as well as the need for climate-controlled environments, the demand for high-quality corrugated polycarbonate panels is increasing in the agricultural industry. Moreover, advancements in panel coatings, light diffusion, and anti-condensation properties are driving the adoption of corrugated polycarbonate panels in greenhouse and agricultural building construction.

Furthermore, there is a growing trend towards the use of corrugated polycarbonate panels in the automotive and transportation sectors. Corrugated polycarbonate panels are utilized in automotive applications such as sunroofs, windows, and exterior trim due to their lightweight, impact resistance, and design flexibility properties. With increasing demand for lightweight materials, improved vehicle aerodynamics, and enhanced passenger comfort, the demand for high-quality corrugated polycarbonate panels is on the rise in the automotive industry. Moreover, advancements in panel design, coatings technology, and integration with advanced driver assistance systems (ADAS) are driving the adoption of corrugated polycarbonate panels in automotive design and manufacturing.

Moreover, technological advancements and innovations are driving the growth of the corrugated polycarbonate panels market. Manufacturers are investing in research and development to develop advanced panel formulations, manufacturing processes, and surface treatments that offer improved performance, durability, and cost-effectiveness. Moreover, advancements in polymer chemistry, extrusion technology, and panel coatings are enabling the production of corrugated polycarbonate panels with tailored properties and functionalities for specific applications. Additionally, innovations in panel design, light diffusion, and energy efficiency are driving the development of next-generation corrugated polycarbonate panels that meet the evolving needs of various industries, further fueling market growth.

Additionally, there is a growing trend towards customization and value-added services in the corrugated polycarbonate panels market. Customers are increasingly seeking panel solutions tailored to their specific application requirements, such as custom dimensions, thicknesses, and light transmission properties. In response, manufacturers are offering comprehensive engineering support, design services, and customization options to meet diverse customer needs effectively. Moreover, value-added services such as pre-cutting, drilling, and assembly are becoming increasingly important as customers seek ready-to-install panel solutions for their construction and building projects.

Leave a Comment