Market Trends

Key Emerging Trends in the CNG Tank Cylinder Market

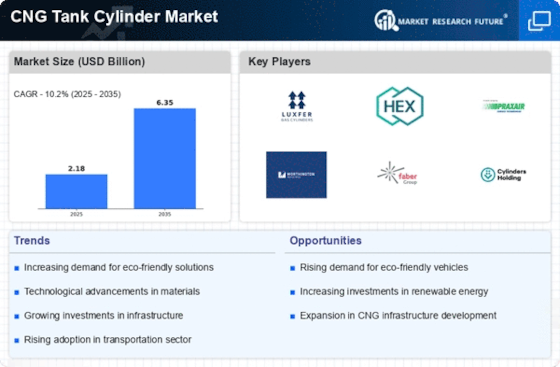

The Compressed Natural Gas (CNG) Tank Cylinder market find itself affected not only by one, but several of the notable trends that we see in the energy sector for transportation throughout the world as more countries find a shift towards ecological energy solutions. Compressed natural gas transportation and storage are becoming popular in modern times with people shying away from fossil fuels. The CNG tank cylinders play a crucial role in enabling this technology. The first to be mentioned is a high demand by car owners for CNG as a fuel for vehicles. As our awareness towards the environment and attempts at reducing the green house gases have seen a rise, CNG has become a cleaner and less harmful alternative for powering our vehicles ranging from cars to even large vehicles like lorries and the buses. This trend is in line then with the other pursuits of utilizing other fuels and the move to greener transport options.

Moreover the market CNG tank cylinders is undergoing great growth as governmental initiatives and regulations support the natural gas usage in the transportation sector. Several governments all over the globe are, in the meantime, adopting programs to give stimuli to the introduction of gas combined cars through tax credits, subsides, and infrastructure construction. This trend testifies the consciousness of countries to air purification, fuel source depletion and climate change as the main concerns for the sector.

The other element that determines the CNG tank cylinders market is innovations in the power of cylinder design and materials. The producer method towards the construction the lightweight and high-strength cylinder for the CNG storage brings to an improved efficiency and safety. Composites comprised of materials like carbon fiber are being used more and more now as CNG safety cylinders which allows the optimum balance of strength and weight reduced with durability. Furthermore, this trend matches with the auto industry ambition to downscale the weight of cars through the lightweighting process in order to get higher fuel efficiency and ultimately, better car performance.

Last but not least, Type IV CNG cylinders for the market of CNG tank cylinders are the subject of much discussion. The development of Type IV CNG cylinders is one of the topics of the discussion. cargo load inside type IV cylinders are plastic lined as well as carbon fiber overwrap is preferred to reduce the weight and and adding more safety features. This is attributed to their capability to perform up to the legal requirements of every second and also to store more hydrogen. Such development indicates the dynamics of cylinder technologies functioning and developments to satisfy the new needs and controlling the CNG movement.

Leave a Comment