Market Trends

Key Emerging Trends in the CNC Machine Market

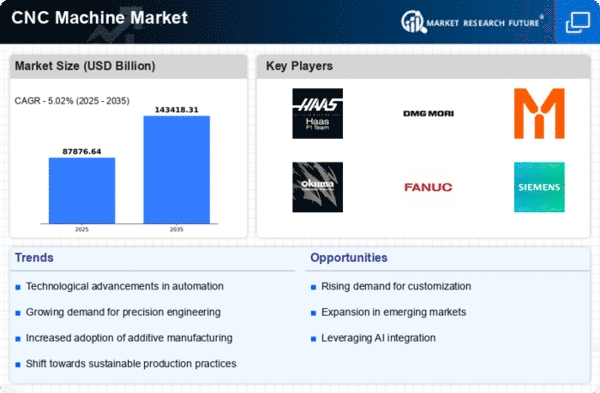

The CNC (Computer Numerical Control) machine market is witnessing significant trends that are reshaping the landscape of precision machining. One dominant trend is the increasing adoption of automation in manufacturing processes. As industries strive for efficiency and precision, CNC machines offer a solution by automating tasks traditionally performed by manual operators. This trend is particularly evident in sectors such as aerospace, automotive, and electronics, where intricate and precise machining is paramount. The integration of automation not only enhances production speed but also reduces human error, leading to improved overall product quality.

Another noteworthy trend is the growing demand for multi-axis CNC machines. As manufacturing requirements become more complex, the need for machines capable of simultaneous multi-axis movements is on the rise. This trend enables manufacturers to create intricate and detailed components in a single setup, reducing production time and costs. Industries like medical devices, mold and die making, and custom tooling benefit significantly from the versatility offered by multi-axis CNC machines.

Additionally, there is a noticeable shift towards the incorporation of advanced technologies in CNC machines. Artificial intelligence (AI) and machine learning are being integrated to optimize machining processes. AI-driven algorithms help in predictive maintenance, identifying potential issues before they cause disruptions and minimizing downtime. CNC machines equipped with smart features also enable adaptive machining, where adjustments are made in real-time based on data feedback, ensuring consistent quality and efficiency.

The CNC machine market is also experiencing a surge in demand for hybrid machines that combine additive manufacturing (3D printing) and subtractive machining capabilities. This trend allows manufacturers to create complex geometries with additive processes and then refine the final product using traditional CNC machining. The hybrid approach offers a unique combination of speed, precision, and design flexibility, making it appealing across various industries, including aerospace and medical.

Furthermore, sustainability has emerged as a key consideration in the CNC machine market. Manufacturers are increasingly focusing on developing eco-friendly and energy-efficient machines. Sustainable machining practices, such as minimizing material waste and optimizing energy consumption, are gaining prominence. As environmental regulations become more stringent, the industry is witnessing a shift towards green technologies and sustainable production methods.

Market trends are also influenced by the rise of small and medium-sized enterprises (SMEs) in the manufacturing sector. The accessibility of compact and affordable CNC machines has empowered smaller businesses to leverage advanced machining capabilities. This democratization of technology enables SMEs to compete on a more level playing field, driving innovation and competitiveness in the CNC machine market.

Globalization and the need for supply chain resilience have led to an increased focus on remote monitoring and connectivity in CNC machines. Manufacturers are incorporating Internet of Things (IoT) technologies to enable real-time monitoring of machine performance, production status, and maintenance needs. This connectivity facilitates data-driven decision-making, predictive analytics, and remote troubleshooting, enhancing overall operational efficiency.

CNC machine market is undergoing dynamic changes driven by automation, multi-axis capabilities, advanced technologies, sustainability, the rise of SMEs, and the integration of IoT. Manufacturers in this space must stay abreast of these trends to meet evolving customer demands and maintain a competitive edge in a rapidly evolving industry. As technology continues to advance, the CNC machine market is likely to witness further innovation, shaping the future of precision machining.

Leave a Comment