Market Analysis

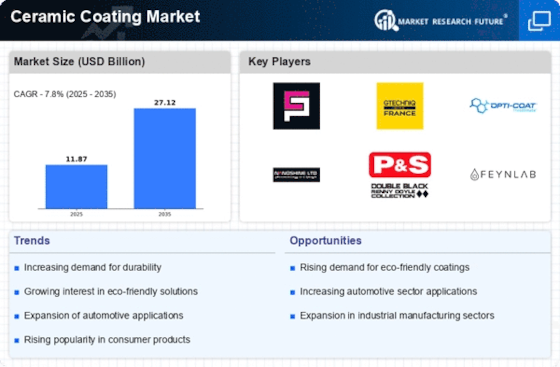

In-depth Analysis of Ceramic Coating Market Industry Landscape

The ceramic coating market holds several promising opportunities that can fuel its growth and expansion within various industries. One notable opportunity lies in the burgeoning renewable energy sector, particularly in solar power generation. Ceramic coatings exhibit excellent thermal stability and resistance to extreme temperatures, making them suitable for solar panels. By applying these coatings, solar panels can enhance their durability, reduce maintenance requirements, and improve overall energy efficiency, thereby unlocking significant potential for ceramic coatings in the renewable energy domain.

Additionally, the aerospace industry presents an opportunity for the ceramic coating market, particularly in the development of next-generation aircraft and spacecraft. The demand for high-performance coatings that can withstand extreme conditions in aerospace applications continues to rise. Ceramic coatings offer lightweight properties and exceptional thermal insulation, making them valuable for protecting aircraft components and spacecraft from extreme heat encountered during atmospheric re-entry. As space exploration and aviation technologies advance, there's a growing need for innovative coatings to support these advancements, thereby creating an opportunity for ceramic coatings.

Moreover, the healthcare sector presents a compelling opportunity for ceramic coatings, particularly in advancing medical technology and devices. The development of advanced medical implants, prosthetics, and surgical instruments requires coatings that are biocompatible, wear-resistant, and capable of supporting intricate designs. Ceramic coatings, with their biocompatibility and durability, have the potential to revolutionize medical devices by extending their lifespan, improving functionality, and ensuring compatibility within the human body. This presents a significant avenue for ceramic coatings to make a substantial impact in the healthcare industry.

Furthermore, the emerging trend of electric vehicles (EVs) and their increasing adoption worldwide provides an opportunity for ceramic coatings. EVs rely on high-performance battery systems, and ceramic coatings exhibit properties that can contribute to enhancing the efficiency and durability of these batteries. By applying ceramic coatings to battery components, such as electrodes and separators, EVs can potentially benefit from improved thermal management, reduced degradation, and increased longevity of battery life, aligning with the growing demand for sustainable and long-lasting energy solutions.

Overall, the ceramic coating market holds promising opportunities across multiple sectors, including renewable energy, aerospace, healthcare, and electric vehicles, paving the way for innovative applications and advancements in various industries.

Leave a Comment