Catechol Size

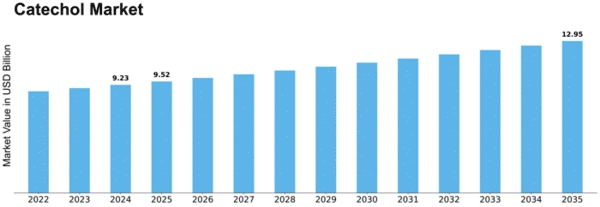

Catechol Market Growth Projections and Opportunities

The catechol market is influenced by a variety of market factors that shape its dynamics and performance. One significant factor is the demand from various industries, including pharmaceuticals, agriculture, and chemical manufacturing. Catechol, also known as 1,2-dihydroxybenzene, serves as a crucial intermediate in the production of numerous chemicals, pharmaceuticals, and pesticides. Its diverse applications make it an essential chemical compound in several sectors, driving demand.

Another vital market factor is the availability and cost of raw materials required for catechol production. Catechol is primarily produced through the hydroxylation of phenol or by the extraction of natural sources such as coal tar. Therefore, fluctuations in the prices of phenol or changes in the availability of coal tar significantly impact the cost structure of catechol production. Moreover, the accessibility of alternative raw materials or production methods can influence market dynamics and competitiveness.

Market regulations and environmental policies also play a crucial role in shaping the catechol market. Regulatory requirements regarding the production, handling, and disposal of catechol impact market participants, influencing production practices and investment decisions. Stringent environmental regulations aimed at reducing pollution and minimizing the environmental footprint of chemical production can lead to changes in manufacturing processes or the adoption of greener alternatives, impacting market dynamics.

Global economic conditions and trade policies are additional market factors that affect the catechol market. Economic downturns or fluctuations in currency exchange rates can impact the affordability of catechol products, affecting demand and pricing. Trade policies, tariffs, and trade agreements also influence the flow of catechol products across borders, affecting market competition and pricing strategies of manufacturers.

Technological advancements and innovations play a pivotal role in shaping the catechol market landscape. Continuous research and development efforts lead to the discovery of novel production processes, improved catalysts, and enhanced purification techniques, driving efficiency gains and cost reductions in catechol manufacturing. Furthermore, technological advancements enable the development of new applications for catechol, expanding its market potential and driving demand growth.

Market competition and industry consolidation are significant factors influencing the catechol market. The presence of multiple manufacturers competing for market share leads to price competition and innovation as companies strive to differentiate their products and capture market demand. Moreover, mergers, acquisitions, and strategic partnerships within the industry can reshape market dynamics, affecting pricing strategies, distribution channels, and overall competitiveness.

Consumer preferences and trends also impact the catechol market, particularly in end-user industries such as cosmetics, pharmaceuticals, and agrochemicals. Shifts in consumer preferences towards natural or environmentally friendly products drive demand for bio-based catechol or products manufactured using sustainable processes. Additionally, changing consumer demographics and lifestyle trends can influence the demand for catechol-containing products, creating opportunities and challenges for market participants.

Leave a Comment