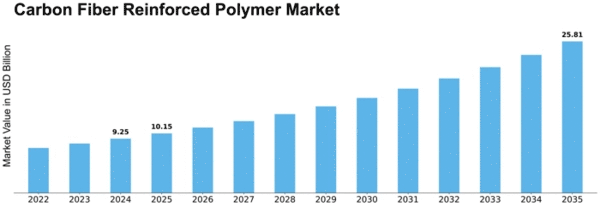

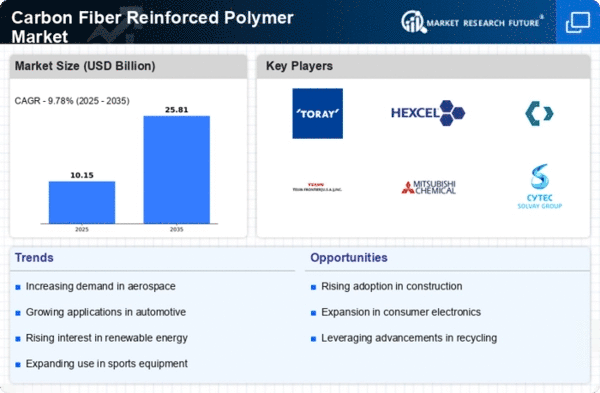

Carbon Fiber Reinforced Polymer Size

Carbon Fiber Reinforced Polymer Market Growth Projections and Opportunities

The global market for carbon fiber reinforced polymer (CFRP) is intricately associated with a range of aspects that altogether steer its development trace and demand conditions. Shareholders in this business must grasp a complete knowledge of these market aspects to make informed conclusions and traverse the competitive model successfully.

The spurring demand for lightweight materials across industries such as aerospace, automotive, and sports equipment is a foremost propelling aspect for the CFRP market. Carbon fiber-reinforced polymers propose a high strength-to-weight ratio, making them suitable for applications where weight decrease is critical.

The renewable energy sphere, particularly wind energy, trusts CFRP for the fabrication of lightweight and permanent wind turbine sails. CFRP's corrosion endurance and high force make it a suitable item for dealing with demanding conditions in wind energy purposes. The global motivation toward renewable energy sources fuels the demand for CFRP in wind turbine construction.

CFRP is greatly exploited in the fabrication of sports apparatus and leisure effects, including golf clubs, bicycles, and tennis rackets. The material's capacity to increase performance via weight decrease and strength makes it widespread in sports production.

The excessive manufacturing expenditures associated with CFRP have occurred as an issue for extensive adoption. However, improvements in manufacturing expertise, such as recycling methods and automated production procedures, are dealing with cost worries and making CFRP more available. Consistent research and development efforts directed at progressing manufacturing efficiency and cutting costs participate in the market's expansion.

Deliberate partnerships, collaborations, and mergers among prime participants illustrate the CFRP market. These proposals authorize businesses to share technologies, pool resources, and develop their product selections to stay competitive. Collaborations and joint ventures also play a part in driving innovation, commanding knowledge from different fields together to create new applications for CFRP.

The accent on sustainability and environmental worries has prompted the development of recycling procedures for CFRP. Efforts to establish efficient recycling methods aim to address end-of-life disposal issues associated with CFRP products. Sustainable operations and the integration of recycled carbon fiber reinforce the fascination of CFRP in industries where environmental considerations are paramount.

Leave a Comment