Market Trends

Key Emerging Trends in the Bench Hydraulic Press Market

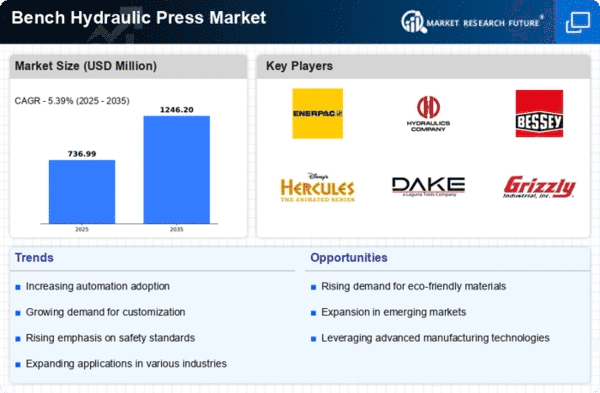

The market trends of bench hydraulic presses are undergoing significant changes driven by technological advancements, industry demands for precision, and the pursuit of efficient manufacturing processes. A notable trend in this market is the integration of advanced control systems and automation features in bench hydraulic presses. Manufacturers are incorporating programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to enhance the precision and control of these presses. This allows for the automation of complex tasks, improved repeatability, and efficient operation, catering to the growing demand for smart and user-friendly machinery in industrial settings.

Moreover, there is a noticeable shift towards customization and versatility in the design of bench hydraulic presses. As industries require specialized solutions for diverse applications, manufacturers are developing presses with adjustable features, modular tooling, and adaptable configurations. This trend addresses the need for flexibility in production processes, allowing users to optimize the bench hydraulic press for specific tasks and accommodate various workpieces.

Energy efficiency is emerging as a key driver in the market for bench hydraulic presses. With a focus on sustainability and reduced operational costs, manufacturers are incorporating energy-efficient hydraulic systems, variable frequency drives, and regenerative capabilities. These features not only contribute to lower energy consumption but also align with environmental goals and regulatory requirements, providing users with more efficient and eco-friendly solutions.

Additionally, advancements in material and design technologies are influencing the market trends for bench hydraulic presses. Manufacturers are exploring lightweight and high-strength materials for the construction of press frames and components. This not only improves the overall durability and longevity of the presses but also facilitates easier handling and transportation. Furthermore, innovations in tooling materials and designs contribute to enhanced precision and performance, allowing users to achieve intricate forming and pressing tasks with greater accuracy.

Technological innovations in digital connectivity and data analytics are influencing the market for bench hydraulic presses. Manufacturers are incorporating connectivity features, such as Industrial Internet of Things (IIoT) capabilities, to enable remote monitoring, predictive maintenance, and real-time performance tracking. This trend aligns with the industry's push towards digitalization and smart manufacturing, providing users with insights into press performance, maintenance needs, and overall productivity.

Furthermore, safety features and compliance with industry standards are gaining prominence in the market for bench hydraulic presses. As workplace safety regulations become more stringent, manufacturers are incorporating advanced safety systems, such as light curtains, interlocking mechanisms, and emergency stop functionalities. This ensures a safer working environment for operators and compliance with occupational health and safety standards.

In terms of market dynamics, competition among bench hydraulic press manufacturers is intensifying. Companies are investing in research and development to enhance the precision, customization, energy efficiency, and safety features of their presses. Meeting user expectations for performance and reliability, adhering to industry standards, and staying at the forefront of technological advancements are critical factors for success in this competitive market. As industries seek more advanced and efficient solutions for pressing and forming operations, the bench hydraulic press market is poised for further innovation and expansion.

Leave a Comment