Market Analysis

In-depth Analysis of Automotive Robotics Market Industry Landscape

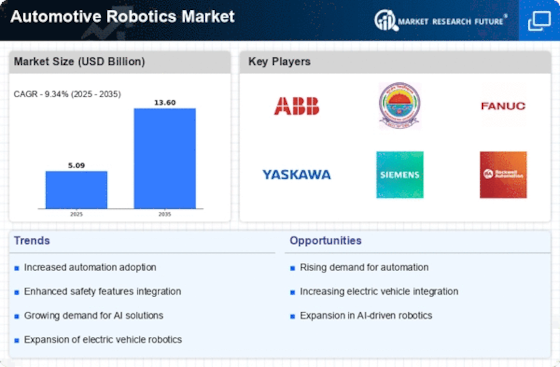

Critical extension is being seen in the automotive robotics market because of mechanical turns of events and moving purchaser inclinations. Business' interest in computerization is expanded by the requirement for assembling cycles to be effective and exact. Advanced mechanics is being carried out by makers to increase efficiency, smooth out creation lines, and keep up with great norms.

Because of the car business' developing accentuation on wellbeing, advanced mechanics are being executed all through the assembling system. Computerized processes including unsafe materials require the utilization of robots, which decrease the threats to human specialists and make a solid work environment, in accordance with the overall pattern toward robotization.

The headway and execution of independent vehicles, which are exceptionally reliant upon complex advanced mechanics for parts like LiDAR sensors and cameras, as well as the accuracy and exactness expected in the mind-boggling fabricating cycles of electric vehicles (EVs) and the auto business' change to electric and independent vehicles, have altogether impelled the automotive robotics market forward.

"Cobots," a cooperative way to deal with assembling in the auto area that joins human workers with mechanical technology to further develop capacities and proficiency, is getting momentum. By consolidating the capacities of people and machines, this system makes an amicable and uncommonly useful work environment.

The Asia-Pacific locale is right now seeing a critical expansion in the interest in auto computerization because of the sped-up industrialization happening in China and India. These nations are progressively becoming communities for the assembling of vehicles, which has prompted a more prominent requirement for mechanization to improve creation processes and oblige the developing volumes.

Hardships in the automotive robotics market confine the capacity of little and medium-sized organizations to carry out the innovation because of the great beginning speculation and talented work requests. Mechanization and economies of scale are adding to the expanded availability of advanced mechanics.

Industry shifts influence the market elements of the automotive robotics area, which means to further develop security, productivity, and the capacity to fabricate electric and independent vehicles. Advanced mechanics will arise as the crucial component of greatness in auto production as the area advances.

Leave a Comment