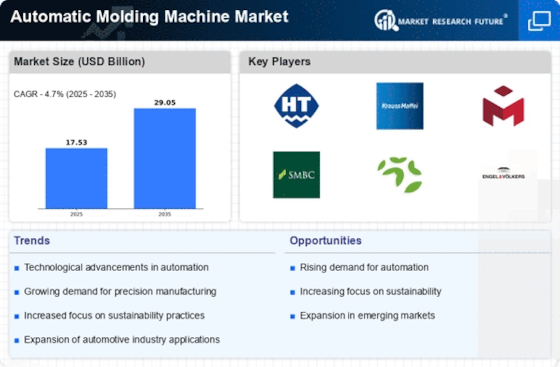

Top Industry Leaders in the Automatic Molding Machine Market

The Competitive Landscape of Automatic Molding Machine Market

In the industrial symphony of mass production, automatic molding machines act as the efficient conductors, orchestrating the precise shaping of materials into a myriad of products. This dynamic market pulsates with the rhythm of innovation and intense competition, demanding an understanding of the strategies, factors, and players shaping its ever-evolving landscape.

Key Players:

- Haitian International Holdings Limited

- Nissei Plastic Industrial Co., Limited

- Engel Austria GmbH

- Chen Hsong Holdings Limited

- Toyo Machinery & Metal Co., Ltd

- Husky Injection Molding Systems Ltd

- Japan Steel Works Limited

- KraussMaffei Group

- UBE Machinery

- Shibaura Machine Co. Ltd.

- Wittmann Battenfeld

- Hillenbrand, INC

Strategies Adopted by Leaders:

- Technological Prowess: Krauss Maffei Wegmann GmbH & Co. KG and Engel Holding GmbH lead the charge with expertise in high-precision injection molding machines, advanced control systems, and AI-powered process optimization, catering to demanding applications like automotive and medical parts.

- Vertical Specialization: Arburg GmbH & Co KG focuses on compact and energy-efficient machines for smaller plastic components, while Sumitomo Heavy Industries Machinery Ltd. targets high-tonnage machines for large industrial parts.

- Partnership Play: Haitian International Holdings Ltd. collaborates with material suppliers and mold manufacturers, fostering seamless integration and material compatibility for customers.

- Open-Source Initiatives and Knowledge Sharing: The Society of Plastics Engineers (SPE) promotes standardization and best practices in molding technology, benefiting the entire industry.

- Focus on Automation and Digitalization: Implementing robotic arms, machine vision systems, and real-time data analytics optimizes production flow, minimizes errors, and improves overall efficiency and throughput.

Factors for Market Share Analysis:

- Performance and Precision: Companies offering machines with high injection speed, cycle times, and repeatability command premium prices and secure market share by enabling high-volume production of consistent and accurate parts.

- Versatility and Material Compatibility: Providing machines capable of handling diverse materials, mold sizes, and application requirements attracts a wider customer base, particularly in contract manufacturing.

- Ease of Use and Maintenance: Offering user-friendly interfaces, intuitive programming tools, and readily available service support simplifies operation and minimizes downtime.

- Cost Competitiveness and Affordability: Balancing advanced features with an attractive price point is crucial for capturing market share, particularly in price-sensitive segments like consumer goods and packaging.

- Focus on Sustainability and Energy Efficiency: Developing energy-saving features, using recycled materials, and minimizing waste generation caters to growing environmental concerns and attracts eco-conscious buyers.

New and Emerging Companies:

- Startups like Fast Radius and Sinta Additive Manufacturing: These innovators focus on developing hybrid manufacturing solutions combining subtractive (molding) and additive (3D printing) technologies, catering to the demand for rapid prototyping and customized plastic parts.

- Academia and Research Labs: MIT's Department of Mechanical Engineering and Stanford University's Department of Materials Science & Engineering explore next-generation technologies like bio-inspired mold designs and intelligent process control algorithms, shaping the future of the market.

- Advanced Material Science Innovations: Companies like Dow Chemical and BASF develop high-performance plastics with improved strength, thermal resistance, and recyclability, expanding application possibilities for molded parts.

Industry Developments:

Haitian International Holdings Limited:

- October 2023: Launched a new series of high-speed, energy-efficient electric servo injection molding machines for packaging applications.

- August 2023: Partnered with a leading university to develop AI-powered mold design and process optimization software for improved part quality and cycle times.

Nissei Plastic Industrial Co., Limited:

- October 2023: Introduced a new line of compact and affordable injection molding machines targeting small and medium-sized businesses.

- August 2023: Collaborated with a material supplier to develop innovative solutions for molding bio-based and recycled plastics.

Engel Austria GmbH:

- October 2023: Unveiled a new generation of all-electric injection molding machines with exceptional precision and melt control for high-performance applications.

- August 2023: Announced plans to expand its production capacity in China to meet increasing demand in the Asian market.