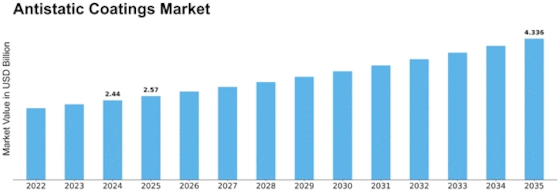

Antistatic Coatings Size

Antistatic Coatings Market Growth Projections and Opportunities

The Antistatic Coatings market is influenced by a multitude of factors that significantly impact its growth and development. To comprehend the dynamics of this industry, it's essential to explore the critical market factors shaping the Antistatic Coatings market. Here are key factors presented in a clear and concise pointer format: Electronics Industry Demand: The primary driver for the Antistatic Coatings market is the robust demand from the electronics industry. Antistatic coatings are crucial in preventing static electricity buildup on electronic components, protecting sensitive devices from electrostatic discharge (ESD) and ensuring their reliable performance. Growth in Manufacturing Activities: As manufacturing activities across various industries expand, the demand for antistatic coatings rises. These coatings find applications in manufacturing processes where static electricity can be a significant concern, such as in the production of plastics, textiles, and automotive components. Increasing Use in Packaging Materials: Antistatic coatings are widely used in packaging materials to prevent static charges that can damage sensitive products. The growth of the e-commerce industry and the need for protective packaging contribute to the increased demand for antistatic coatings in materials like films, wraps, and containers. Surge in Electronics Consumption: The increasing global consumption of electronic devices, including smartphones, tablets, and wearable technology, boosts the demand for antistatic coatings. These coatings are essential in the production and assembly of electronic gadgets to maintain the integrity of delicate electronic components. Stringent Industry Standards: Compliance with industry standards and regulations regarding static control in specific applications, such as electronics and healthcare, drives the adoption of antistatic coatings. Manufacturers must adhere to these standards to ensure the effectiveness and reliability of their products in various industries. Rise in Healthcare Applications: Antistatic coatings play a vital role in healthcare settings where static electricity can pose risks to sensitive medical equipment. The increasing use of electronic medical devices and diagnostic equipment contributes to the demand for antistatic coatings in the healthcare sector. Technological Advancements: Ongoing advancements in coating technologies contribute to the growth of the antistatic coatings market. Innovations in formulations, application methods, and the development of more effective and durable coatings enhance their performance in diverse industrial applications. Expansion of Automotive Manufacturing: The automotive industry's expansion, coupled with the increasing integration of electronic components in vehicles, fuels the demand for antistatic coatings. These coatings are applied to various automotive parts and components to prevent static-related issues during manufacturing and assembly processes. Concerns About Explosive Environments: Industries dealing with flammable or explosive materials, such as chemicals and petrochemicals, utilize antistatic coatings to mitigate the risk of static electricity-induced fires or explosions. This safety consideration drives the adoption of antistatic coatings in potentially hazardous environments. Environmental and Safety Standards: The increasing focus on environmental sustainability and safety standards impacts the choice of coatings in various industries. Antistatic coatings that meet eco-friendly criteria and safety regulations are preferred, influencing purchasing decisions across sectors. Cost Considerations and Affordability: While the benefits of antistatic coatings are significant, cost considerations remain a factor for industries adopting these coatings. Manufacturers need to balance the performance benefits with the overall cost-effectiveness of antistatic coatings to ensure market competitiveness. Global Supply Chain Dynamics: The globalization of supply chains affects the availability and pricing of antistatic coatings. Companies operating in the market must navigate international trade dynamics, addressing factors such as tariffs, logistics, and regional variations in demand.

Leave a Comment