Market Trends

Key Emerging Trends in the Air Separation Plant Market

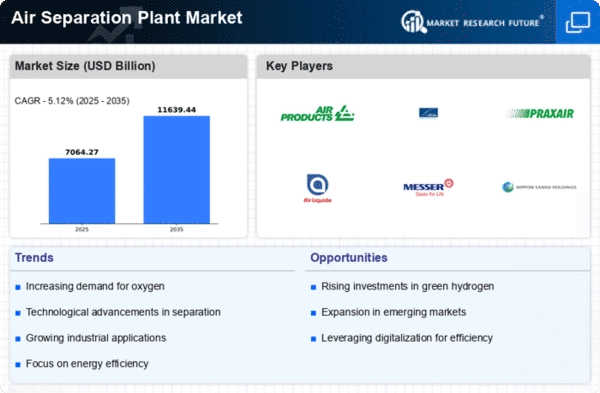

The air separation plant market is characterized by important trends that reflect the changing landscape of industrial and manufacturing domains. Air separation plant market growth is boosted by the fact that, as industries grow on an international scale so will demand for industrial gases such as oxygen nitrogen and argon. An important trend is the increase in adoption of ASUs across several industries, such as steel industry, chemical industry, health care sector and electronics. This boom is due to the vital role that these plants play in manufacturing and distributing pure gases used for various industrial applications. Moreover, environmental issues and the search for sustainable principles now play an important role in determining market tendencies. There has been increasing focus on using efficient energy technologies and environmentally responsible solutions in the air separation plant market. However, manufacturers increasingly aim to produce air separation units which would reduce energy consumption and contribute less greenhouse gases as well as provide a higher level of operational effectiveness. With the rest of the world moving towards sustainable development goals and minimizing industrial activities on environment, this shift is in line with that. One of the major trends is technological developments in air separation processes. Along with continuous innovation, new technologies are being delivered to improve the efficiency and economic viability of air separation plants. Among the emerging technologies, cryogenic distillation, pressure swing adsorption (PSA) and membrane separation are popular in the market. These innovations in the gas separation not only promote efficiency but they also contribute to this industry competitiveness of air separation plants. The market is also seeing a significant spike in the demand from developing countries especially Asia-Pacific and Latin America. The need for industrial gases in these regions is on the rise due to rapid industrialization and urbanization, which presents vast opportunities for air separation plant producers. Other factors that contribute to the market growth include rising concern for healthcare infrastructure and ever-increasing demand of medical gases. Supply chain resilience and localization have since emerged as key aspects following global uncertainties like COVID-19. Manufacturers are engaging in a critical reassessment of supply chain networks, focusing on local production units and functional planning alternatives. This trend seeks to maintain stable supplies of industrial gases, even in difficult conditions and minimize dependence on international logistics.

Leave a Comment