Aerospace Floor Panel Size

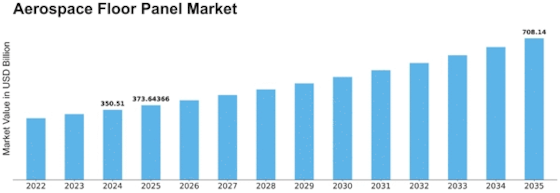

Aerospace Floor Panel Market Growth Projections and Opportunities

The aerospace floor panel market is significantly influenced by various factors that shape its growth and development. One crucial factor is the increasing demand for lightweight materials and advanced structural solutions in the aerospace industry. As aircraft manufacturers strive to improve fuel efficiency, reduce emissions, and enhance performance, there is a growing need for innovative floor panel solutions that offer high strength-to-weight ratios while meeting stringent safety and regulatory requirements. Aerospace floor panels play a critical role in the structural integrity of aircraft cabins, providing support for passenger seating, cargo loading, and equipment installation. Manufacturers are investing in research and development to design and produce lightweight floor panels using advanced composite materials, such as carbon fiber reinforced polymers (CFRP) and honeycomb structures, to meet the evolving needs of the aerospace market.

Moreover, technological advancements drive market growth and innovation in the aerospace floor panel sector. Advances in materials science, manufacturing processes, and design techniques enable the development of floor panels with improved mechanical properties, durability, and fire resistance. Manufacturers are incorporating features such as integrated wiring harnesses, acoustic insulation, and modular designs into floor panel systems to enhance functionality and ease of installation. Additionally, digital design tools, computer-aided engineering (CAE) simulations, and additive manufacturing technologies enable companies to optimize floor panel designs, reduce production costs, and accelerate time-to-market, driving market competitiveness and product innovation.

Furthermore, regulatory requirements and safety standards significantly influence the aerospace floor panel market. Aviation authorities, such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA), impose strict regulations and certification requirements that govern the design, testing, and installation of aircraft interior components, including floor panels. Compliance with these regulations is essential to ensure the airworthiness, structural integrity, and passenger safety of aircraft cabins. Manufacturers must adhere to certification standards, such as those outlined in the FAA's Technical Standard Order (TSO) or EASA's European Technical Standard Order (ETSO), to obtain approval for their floor panel products, driving market demand for compliant solutions.

Additionally, market demand for aerospace floor panels is driven by factors such as aircraft production rates, fleet expansion, and retrofitting activities. With growing air travel demand and increasing aircraft orders from airlines and leasing companies, aircraft manufacturers are ramping up production rates to meet market demand. This trend fuels market demand for floor panels as aircraft OEMs require reliable and cost-effective solutions to outfit new aircraft deliveries. Moreover, as airlines upgrade their fleets, retrofit older aircraft models, and invest in cabin refurbishment programs, there is a sustained demand for replacement floor panels and retrofit solutions to modernize cabin interiors and enhance passenger comfort, driving market growth for aftermarket floor panel products and services.

Furthermore, the impact of the COVID-19 pandemic has affected the aerospace floor panel market, causing disruptions in supply chains, production schedules, and demand for commercial air travel. With travel restrictions, border closures, and reduced passenger traffic, airlines have deferred new aircraft deliveries, fleet expansion plans, and cabin refurbishment projects, leading to decreased demand for floor panels and related interior components. However, as air travel gradually recovers and passenger confidence returns, airlines are expected to resume fleet expansion and cabin modernization initiatives, driving market demand for aerospace floor panels and supporting recovery in the aerospace interior components sector.

Moreover, market factors such as sustainability initiatives, passenger comfort trends, and aircraft interior customization drive innovation and differentiation in the aerospace floor panel market. With increasing environmental awareness and sustainability goals, aircraft manufacturers and airlines are exploring lightweight, recyclable, and eco-friendly materials for floor panel solutions to reduce carbon footprint and environmental impact. Additionally, passenger comfort and satisfaction are becoming increasingly important factors in aircraft interior design, leading to the adoption of floor panel solutions that offer enhanced acoustic insulation, vibration damping, and ergonomic features. Moreover, as airlines seek to differentiate their brand and enhance the passenger experience, there is a growing trend towards customizable floor panel designs, finishes, and configurations that reflect airline branding and aesthetics, driving market demand for bespoke interior solutions.

Leave a Comment