Market Analysis

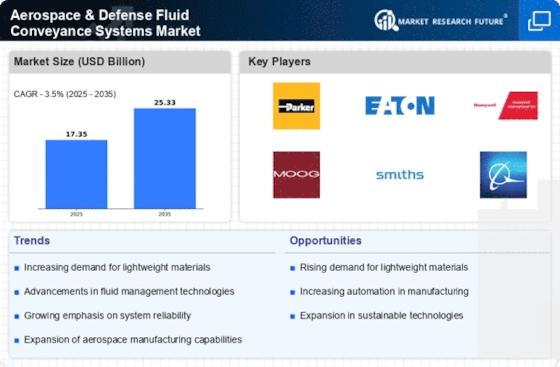

In-depth Analysis of Aerospace and Defense Fluid Conveyance Systems Market Industry Landscape

The Aerospace & Defense Fluid Conveyance Systems market is influenced by a multitude of factors, reflecting the intricate needs of the aerospace and defense industries, technological advancements, regulatory requirements, and economic conditions. Fluid conveyance systems play a critical role in aircraft and defense platforms, facilitating the transport of fluids such as fuel, hydraulic fluid, and coolant to various subsystems and components. These systems encompass a wide range of components, including hoses, tubes, fittings, connectors, and valves, which are essential for the reliable and efficient operation of aerospace and defense platforms.

One significant driver of the demand for Aerospace & Defense Fluid Conveyance Systems is the continuous evolution and modernization of aircraft and defense platforms. As aerospace manufacturers develop new aircraft models and defense contractors innovate in military platforms, there is a growing need for fluid conveyance systems that meet the stringent performance, reliability, and safety requirements of modern aerospace and defense applications. Advanced fluid conveyance systems are essential for delivering fluids to critical subsystems such as engines, landing gear, flight controls, and weapon systems, ensuring optimal performance and operational readiness.

Technological advancements play a pivotal role in shaping the dynamics of the Aerospace & Defense Fluid Conveyance Systems market. Innovations in materials science, manufacturing processes, and design methodologies enable the development of lightweight, durable, and high-performance fluid conveyance components that meet the demanding requirements of aerospace and defense applications. Advanced materials such as titanium, stainless steel, and composite materials offer superior strength-to-weight ratios, corrosion resistance, and fatigue life, allowing manufacturers to produce fluid conveyance components that are lighter, more reliable, and more resistant to environmental wear and tear.

Furthermore, regulatory requirements and safety standards drive the demand for Aerospace & Defense Fluid Conveyance Systems. Aviation authorities such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) impose stringent regulations and certification requirements on aerospace components, including fluid conveyance systems, to ensure airworthiness, reliability, and safety of aircraft. Compliance with these regulations is essential for aerospace manufacturers and suppliers, driving investment in research, development, and testing to meet certification requirements and obtain regulatory approval for fluid conveyance systems.

Moreover, the increasing focus on fuel efficiency, environmental sustainability, and operational efficiency in the aerospace and defense industries influences the dynamics of the Aerospace & Defense Fluid Conveyance Systems market. Aerospace manufacturers and defense contractors seek to reduce fuel consumption, emissions, and lifecycle costs of aircraft and defense platforms through lightweighting, aerodynamic optimization, and efficient fluid management systems. Advanced fluid conveyance systems play a critical role in achieving these objectives by minimizing hydraulic losses, reducing fluid leakage, and optimizing fluid flow distribution, thereby improving overall system efficiency and performance.

Additionally, economic factors such as defense budgets, commercial air travel demand, and geopolitical tensions impact the dynamics of the Aerospace & Defense Fluid Conveyance Systems market. Fluctuations in defense spending by governments and defense procurement priorities influence market demand for fluid conveyance systems in military aircraft, rotorcraft, and land-based defense platforms. Similarly, trends in commercial air travel demand, aircraft orders, and fleet expansion plans drive market demand for fluid conveyance systems in commercial airliners, regional jets, and business aircraft. Moreover, geopolitical tensions and security threats drive investments in defense capabilities and homeland security, stimulating market growth for fluid conveyance systems in military and security applications.

However, challenges exist in the Aerospace & Defense Fluid Conveyance Systems market, including supply chain disruptions, cost pressures, and technology obsolescence. Aerospace manufacturers and suppliers must navigate complex supply chains, manage inventory levels, and mitigate risks related to raw material shortages, geopolitical instability, and transportation disruptions. Moreover, cost pressures from OEMs and defense primes require suppliers to optimize production processes, reduce manufacturing costs, and improve operational efficiency to remain competitive in the market. Additionally, rapid technological advancements and evolving customer requirements necessitate continuous innovation and investment in research and development to develop next-generation fluid conveyance solutions that meet the evolving needs of the aerospace and defense industries.

Leave a Comment