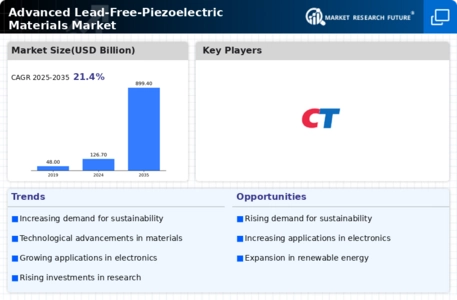

Top Industry Leaders in the Advanced Lead-Free Piezoelectric Materials Market

The Competitive Landscape of Advanced Lead-Free Piezoelectric Materials Market

Across the vibrant landscapes of biomedical imaging, ultrasonic sensors, and energy harvesting, an invisible dance unfolds - materials vibrate with piezoelectric magic, converting mechanical energy into electricity and vice versa. This dynamic market for advanced lead-free piezoelectric materials, pulsates with the competitive hum of players orchestrating this high-precision performance. Understanding their strategies, the factors for market share analysis, and the overall competitive scenario is crucial for navigating this booming terrain.

Key Players:

- Kyocera

- Sumitomo Chemical

- PI Ceramic GmbH

- Yuhai Electronic Ceramic

Strategies Adopted by Leaders

- Technological Prowess KYOCERA and Morgan Technical Ceramics lead the charge with expertise in high-performance lead-free piezoelectrics like barium titanate and lanthanum-based ceramics, catering to demanding applications in medical ultrasound and aerospace sensors.

- Vertical Specialization TDK Electronics focuses on cost-effective lead-free solutions for consumer electronics like microphones and haptic actuators, while Murata Manufacturing targets niche applications like energy harvesting devices and wireless sensors.

- Partnership Play Saint-Gobain collaborates with research institutions and material developers, co-creating and bringing innovative lead-free piezoelectrics to the market.

- Focus on Performance Optimization Implementing advanced material processing techniques and dopant chemistries enhances piezoelectric properties like sensitivity, efficiency, and temperature stability, securing premium prices and market share.

- Embrace of Sustainability and Environmental Credentials Eliminating lead from piezoelectric materials meets stringent environmental regulations and enhances brand image, particularly in eco-conscious markets.

Factors for Market Share Analysis

- Piezoelectric Performance Companies offering lead-free materials with superior electromechanical coupling coefficients, permittivity, and temperature stability command premium prices and secure market share by enabling high-precision devices and efficient energy conversion.

- Cost Competitiveness and Affordability Balancing advanced performance with an attractive price point is crucial for capturing market share, particularly in price-sensitive segments like consumer electronics and emerging markets.

- Scalability and Manufacturability Efficient production processes and readily available raw materials contribute to cost-effectiveness and ensure consistent supply of lead-free piezoelectrics, fostering market adoption.

- Compatibility with Existing Applications and Devices Seamless integration of lead-free materials with existing manufacturing processes and device designs minimizes disruption and accelerates market penetration.

- Focus on Sustainability and Environmentally Friendly Processes Utilizing recycled materials and adopting closed-loop production systems resonates with environmentally conscious customers and opens doors to green procurement policies.

New and Emerging Companies

- Startups like Piezotech and Akoustis Technologies These innovators focus on developing novel lead-free piezoelectrics like single-crystal materials and thin-film composites, aiming to revolutionize piezoelectric performance and miniaturization for advanced applications.

- Academia and Research Labs MIT's Materials Science and Engineering Department and Japan's National Institute for Materials Science explore disruptive technologies like bio-inspired piezoelectrics, nanostructured materials, and flexible piezoelectrics, shaping the future of the market.

- Advanced Software and Simulation Tools Companies like COMSOL and ANSYS develop computer-aided design and simulation platforms for optimizing piezoelectric material design and device performance, accelerating innovation and reducing development costs.

Industry Developments:

Kyocera:

- September 2023: Introduced a new standard range of 230V silicon nitride (SN) igniters for gas stoves, boilers, water heaters, and industrial or domestic gas furnaces.

- February 2023: Collaborated with a university research group to develop new lead-free piezoelectric ceramics with enhanced piezoelectric coefficients and temperature stability.

Sumitomo Chemical:

- October 2023: Partnered with a leading electronics manufacturer to develop and supply high-performance lead-free piezoelectric materials for next-generation ultrasound transducer applications.

- May 2023: Unveiled a new series of lead-free piezoelectric ceramics based on barium titanate with improved mechanical properties for structural health monitoring applications.

PI Ceramic GmbH:

- October 19, 2023: Showcased their extensive portfolio of lead-free piezoelectric materials and devices at the International Conference on Smart Materials and MEMS, highlighting their high-precision sensors and actuators.

- March 2023: Secured a contract with a European aerospace company to provide custom-designed lead-free piezoelectric transducers for vibration control in satellite structures.