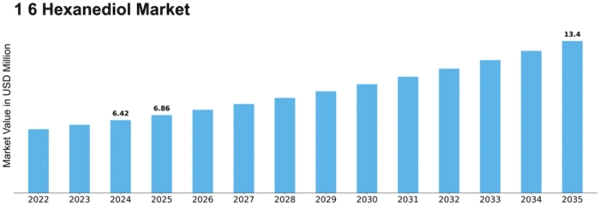

1 6 Hexanediol Size

1 6 Hexanediol Market Growth Projections and Opportunities

The 1,6 Hexanediol Market is subject to a range of factors that collectively shape its growth, demand patterns, and overall competitiveness. These factors encompass industry-specific dynamics, technological advancements, and broader economic and environmental considerations. Here's a succinct breakdown of key market factors defining the landscape of the 1,6 Hexanediol Market:

Polyurethane Production Hub:

1,6 Hexanediol serves as a vital component in the production of polyurethane, a versatile polymer used in various applications, including coatings, adhesives, and elastomers.

The demand for polyurethane, driven by its diverse applications in industries such as construction and automotive, significantly influences the consumption of 1,6 Hexanediol.

Textile and Spandex Manufacturing:

The textile industry relies on 1,6 Hexanediol in the production of spandex fibers, which are known for their elasticity and comfort.

The growth in the textile sector, with increasing demand for stretchable fabrics in apparel, contributes to the demand for 1,6 Hexanediol.

Expanding Automotive Sector:

1,6 Hexanediol finds application in the automotive industry for the production of engineering plastics and polyurethane-based components.

As the automotive sector continues to grow, driven by innovation and consumer demand for lightweight and durable materials, the demand for 1,6 Hexanediol rises.

Adhesives and Sealants Formulation:

The chemical's properties make it a valuable ingredient in the formulation of adhesives and sealants used in construction, manufacturing, and various industrial applications.

The demand for efficient bonding and sealing solutions across industries contributes to the use of 1,6 Hexanediol in adhesive formulations.

Asia-Pacific as a Key Consumption Region:

The Asia-Pacific region, particularly China, stands out as a major consumer and producer of 1,6 Hexanediol.

The region's robust industrial and manufacturing activities contribute significantly to the overall demand and supply dynamics of the 1,6 Hexanediol market.

Resilience to Economic Trends:

Economic factors, including GDP growth, industrial output, and infrastructure investments, play a role in shaping the overall demand for 1,6 Hexanediol.

The resilience of the chemical's demand to economic fluctuations reflects its essential role in various industries.

Research and Development Initiatives:

Ongoing research and development efforts focus on innovative applications and production processes for 1,6 Hexanediol.

Innovations in technology contribute to the development of more efficient and cost-effective production methods and broaden the range of applications for the chemical.

Environmental and Regulatory Compliance:

Stringent environmental regulations impact the production and use of chemicals, including 1,6 Hexanediol.

Compliance with environmental and safety standards is essential for manufacturers to navigate regulatory landscapes and ensure market acceptance.

Fluctuations in Raw Material Prices:

The 1,6 Hexanediol market is influenced by fluctuations in the prices of raw materials such as adipic acid and butadiene.

Price volatility poses challenges for manufacturers in maintaining stable pricing strategies and profit margins.

Consumer Trends towards Sustainable Products:

Growing consumer awareness and preferences for sustainable and eco-friendly products influence the 1,6 Hexanediol market.

Manufacturers exploring sustainable production processes and bio-based alternatives align with evolving consumer expectations.

Packaging Industry Demand:

1,6 Hexanediol finds application in the packaging industry, contributing to the production of films, coatings, and other packaging materials.

The packaging industry's constant quest for improved materials aligns with the chemical's versatility and functionality in packaging applications.

Global Supply Chain Dynamics:

The 1,6 Hexanediol market is influenced by global supply chain dynamics, including trade patterns, logistics, and geopolitical factors.

Market participants need to navigate the complexities of the global supply chain to ensure a stable and efficient flow of raw materials and finished products.

Leave a Comment