Market Share

Welding shielding gas Market Share Analysis

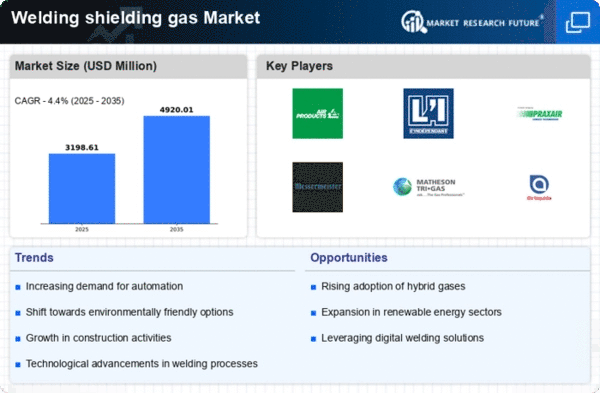

The welding gas/shielding gas market has witnessed dynamic trends in recent years, reflecting the evolving landscape of the welding industry. As a critical component in various welding processes, the demand for welding gas is intrinsically linked to the growth and changes in the broader manufacturing sector. One notable trend shaping the market is the increasing adoption of advanced welding technologies. As industries strive for higher efficiency and precision in their welding operations, there is a growing reliance on processes such as gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW). These advanced techniques often require specific shielding gases to optimize weld quality, driving the demand for specialized gas formulations.

Furthermore, the emphasis on sustainable practices and environmental concerns has spurred a shift towards eco-friendly welding gases. Manufacturers and end-users are increasingly opting for gases that minimize carbon emissions and contribute to a greener welding process. This sustainability trend aligns with global initiatives to reduce the environmental impact of industrial activities, influencing the choices made in the welding gas market.

The globalization of manufacturing activities has also impacted the welding gas market. As companies expand their operations across borders, there is a growing need for standardized welding processes and materials. This has led to the adoption of common welding gas specifications, promoting consistency in welding outcomes and simplifying supply chain management. The standardization trend has implications for both large multinational corporations and smaller enterprises, as they seek to streamline their operations and ensure product quality across diverse geographical locations.

In addition to these global trends, regional factors play a significant role in shaping the welding gas market. Economic growth in emerging markets has led to increased industrialization, driving the demand for welding gases. Countries experiencing rapid infrastructure development and manufacturing expansion contribute substantially to the overall market growth. On the other hand, mature markets with established industrial sectors are witnessing a shift towards automation and smart welding technologies, influencing the types and volumes of welding gases consumed.

Technological advancements in the production and distribution of welding gases have also impacted market dynamics. The development of innovative gas packaging solutions, such as high-pressure cylinders and advanced gas delivery systems, enhances the efficiency and safety of welding processes. Additionally, digitalization and the integration of Internet of Things (IoT) technologies in gas supply chains enable real-time monitoring and optimization, ensuring a seamless and uninterrupted supply of welding gases to end-users.

However, challenges persist in the welding gas market. Fluctuating raw material prices, geopolitical uncertainties, and regulatory changes can impact the cost structure and profitability of industry players. Moreover, the market faces the ongoing challenge of balancing the need for high-performance gases with cost considerations, especially in price-sensitive industries.

In conclusion, the welding gas/shielding gas market is navigating a complex landscape shaped by a combination of global and regional trends. The industry is witnessing a paradigm shift towards advanced and sustainable welding technologies, coupled with the demand for standardized processes in an increasingly interconnected world. As manufacturing processes continue to evolve, the welding gas market is expected to adapt to meet the changing needs of diverse industries while addressing challenges posed by economic, environmental, and technological factors.

Leave a Comment