- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Global Water-Soluble Polymer Market Overview

Water-Soluble Polymer Market Size was valued at USD 33.37 billion in 2022. The Water-Soluble Polymer industry is projected to grow from USD 35.19 Billion in 2023 to USD 55.10 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 5.76% during the forecast period (2023 - 2030).

Water-soluble polymers can be employed in a variety of applications as stabilisers, thickeners, emulsifiers, lubricity aids, and rheology modifiers. Demand is expected to increase throughout the review period due to the increased requirement for water-soluble polymers in the petroleum industry. By 2030, the market for water-soluble polymers is anticipated to reach USD 57.32 billion, expanding at a CAGR of 6.18 percent. Also, throughout the projected period, market participants would profit from environmentally friendly advancements such bio-based acrylamide and rising demand for polyvinyl alcohol polymers in green packaging for domestic goods, personal care products, food, and pharmaceuticals.

Due to expanding uses in personal care products, construction materials, household detergents, paint, textiles, and the treatment of municipal and industrial wastewater. Demand for the product could rise in the next years because of environmental rules governing manufacturing company effluent discharge and environmental protection. Due to the high customizability of these polymers, fluid characteristic improvement and precise control are now possible. These plastics are used in well drilling for a variety of purposes, including as anti-swelling agents for clay, mud fluid loss control agents, solid suspending agents, rheology modifiers, and high temperature/pressure applications. Yet, during the process, these polymers are exposed to a particularly harsh chemical, mechanical, and thermal environment. Due to this problem, high molecular weight materials degrade and disintegrate, affecting their physicochemical characteristics and stunting market expansion.

Water-Soluble Polymer Market Trends

-

Growing Oil & Gas Industry Will Be the Growth Engine for the Market

In the oil and gas business, especially in the upstream and midstream segments, water-soluble polymers are widely used. It is employed in drilling, well completion, cementing, the production of oil and gas wells, the use of diverting agents, well stimulation, the management of deposit formation, and the treatment of oil and oil-contaminated systems. Oil companies heavily rely on chemically enhanced oil recovery and hydraulic fracturing processes to reach maximum production levels and meet escalating energy demand. 40% of the oil wells in the world are thought to be stimulated by hydraulic treatment. The majority of these hydraulic fracturing procedures stimulate unconventional oil and gas reserves by using water-based fracturing fluid. In order to enhance the performance of water-based fluids in terms of proppant transport, fluid loss to the formation, and increase in fracture dimension, water-soluble polymer additives are used.

The plastic guar and its derivatives, xanthan gum, hydroxyethylcellulose, and hydrolyzed polyacrylamide are examples of these additives. Alkali surfactants, which are employed in the chemically enhanced oil recovery (CEOR) method to recover oil trapped in capillaries and increase well production life and profitability, are based on this principle. Water soluble plastic has been widely used by mud engineers to improve and control the drilling fluid's properties to meet the needs of certain oil and gas reservoirs. These polymers' great degree of customizability has made it possible to precisely control and improve the desired fluid characteristic. Clay anti-swelling agent, fluid-loss control agent for mud, rheology modifier, solid suspending agent, and high temperature/pressure applications are just a few of the uses for these plastics in well drilling.

August 2022: Jointly launched by BASF and Nippon Paint China, the leading coatings manufacturer, this is an environmentally friendly industrial packaging used for dry mortar series products of Nippon Paint. The new packaging material uses the Joncryl High-Performance Barrier (HPB), a water-based acrylic dispersion of BASF, as the barrier material.

Water-Soluble Polymer Market Segment Insights

Water-Soluble Polymer Application Insights

Due to the increasing demand for effluent treatment, wastewater treatment made up most of the market in 2022. Growing effluent production from various manufacturing businesses increases the need for water treatment, which propels market expansion. Strict environmental regulations will aid in the market's expansion as a result of rising ecological concerns in the US, UK, China, and Germany. Environmental rules governing the discharge of wastewater and the quality of drinking water may increase demand for synthetic polymers.

In June 2021, for 3D printed microporous objects, Infinite Material Solutions has introduced a novel water-soluble thermoplastic.

In February 2021, an revolutionary new resin called Hydropol was created by the U.K.-based Aquapak Polymers and is packaged as a typical plastic pellet. Since the products are water soluble and safely biodegrade into mineralized natural biomass, water, and carbon dioxide, they are thought to reduce plastic pollution.

Figure 2: WATER-SOLUBLE POLYMER MARKET, BY APPLICATION, 2022 & 2030 (USD BILLION)

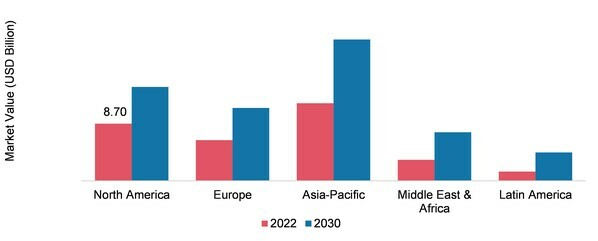

Water-Soluble Polymer Regional Insights

Rising demand from the wastewater treatment industry is anticipated to be the main driver in the Asia Pacific area. Due to growing environmental concerns and expenditures from corporate and governmental parties to stop ecological damage, the municipal and industrial wastewater treatment sector will expand. For instance, China intends to increase its investment in rural wastewater treatment systems by USD 18.5 billion during their 14th five-year plan (2021-2025), which follows an investment of USD 80.7 billion in city wastewater treatment systems during their 13th five-year plan (2015-2020). Water soluble polymers are produced and consumed in large quantities in China. Given that the wastewater treatment sector is anticipated to grow over the course of the forecast period, there will likely be an increase in the demand for polymers like polyacrylamide in the region. Polyacrylamide is a common flocculating and coagulating agent in wastewater treatment.

Figure 2: WATER-SOLUBLE POLYMER MARKET, BY REGION, 2022 & 2030 (USD BILLION)

Source: Secondary Research, Primary Research, MRFR Database and Analyst Review

Water-Soluble Polymer Key Market Players & Competitive Insights

The market for water soluble polymers is extremely competitive, with major market players developing new products, partnering with other companies, and acquiring smaller companies to expand their production capabilities, product portfolios, and industries across the globe.

BASF and Nippon Paint China, the leading coatings manufacturer, have jointly launched eco-friendly industrial packaging that incorporates the Nippon Paint dry-mixed mortar series products. This new packaging material is commercialized for producing a dry mortar product of Nippon Paint, using BASF’s water-based acrylic dispersion Joncryl High-Performance Barrier (HPB) as the barrier material.

Kemira Oyj announced in February 2022 that it had begun global-scale production of its newly introduced polyacrylamide polymer based on biobased feedstock. The first shipment of commercial volumes has been dispatched to one of Helsinki Region Environmental Services (HSY) wastewater treatment plants for testing.

Researchers at the Tokyo Institute of Technology developed a peptide sensor in Nov 2021 that can discriminate polymers soluble in water from those entering sewers, which is another problem similar to microplastic pollution. It offers machine learning technology that uses peptides bonded polymer for the detection and quantification of pollutants simultaneously present in the solution.

In its two factories, starting in May 2021, LG Chem will produce bi-based polymers. ISCC Plus has certified LG Chem under nine bio-balanced products: SAP, PO(polyolefin), and PC(polycarbonate) compounds, among others.

Flexibility and slightly increased capacity were added to BASF’s Ludwigshafen plant producing water-soluble polyacrylate in January 2020. An expanded plant in specialty chemicals at the manufacturing stage is expected to provide enhanced capacity to BASF’s customers in household and commercial cleaning product industries, as well as the chemical and formulator industries.

Key Companies in the Water-Soluble Polymer market includes

- SNF Group (France)

- Kemira (Finland)

- BASF SE (Germany)

- Ashland (US)

- KURARAY CO., LTD. (Japan)

- DuPont (US)

- Arkema S.A. (France)

- The Dow Chemical Company (US)

- Nitta Gelatin, NA Inc. (US)

- Gantrade Corporation (US)

- Akzo Nobel N.V. (Netherlands)

- Sumitomo Seika Chemicals Co., Ltd. (Japan)

- CP Kelco U.S. (US)

- Shandong polymers Bio-chemicals Co. Ltd. (China)

- Mitsubishi Chemical Corporation (Japan)

Water-Soluble Polymer Industry Developments

In March 2022: Kemira has started producing a novel polymer at full capacity using biobased feedstock. One of the wastewater treatment facilities operated by Helsinki Area Environmental Services (HSY) received the first commercial quantities for testing. Kemira offers this biomass-balanced polyacrylamide, a water-soluble polymer, as a functionally equivalent alternative for this specific polymer type. These polymers can be used in a number of industries, including the water and energy sectors as well as papermaking applications with significant demand.

In November 2021: A peptide sensor was developed by researchers at the Tokyo University of Technology to identify water-soluble polymers in wastewater, a severe problem on par with microplastics. The innovative technique creates a machine learning system that can recognise and quantify several pollutants in a single solution via peptide-polymer bonding.

In Nov 2021, Tokyo Institute of Technology researchers created a peptide sensor able to detect water-soluble polymers in sewerage – an issue on par with microplastics. The clever method uses artificial intelligence and peptides coupled with different polymers to identify and quantify multiple contaminants simultaneously within one sample.

In May 2021, LG Chem will produce bio-based polymers at two sites. SAPs and PC compounds, besides nine other types such as POs (polyolefins), were granted ISCC Plus accreditation by LG Chem, which means that they have been manufactured according to an approved scheme based on internationally recognized sustainability criteria.

Water-Soluble Polymer Market Segmentation

Water-Soluble Polymer Raw Material Outlook

- Synthetic

- Semi-Synthetic

- Natural

Water-Soluble Polymer Type Outlook

- Polyacrylamide and Copolymers

- Guar Gum & Derivatives

- Casein

- Polyvinyl Alcohol

- Gelatin,

- Polyacrylic Acid

- Others

Water-Soluble Polymer Regional Outlook

- North Americas

- USA

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- Australia

- South Korea

- Australia

- Rest of Asia-Pacific

- Middle East & Africa

- Turkey

- Israel

- South Africa

- GCC

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Mexico

- Rest of LATAM

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.